bluwolf

Member

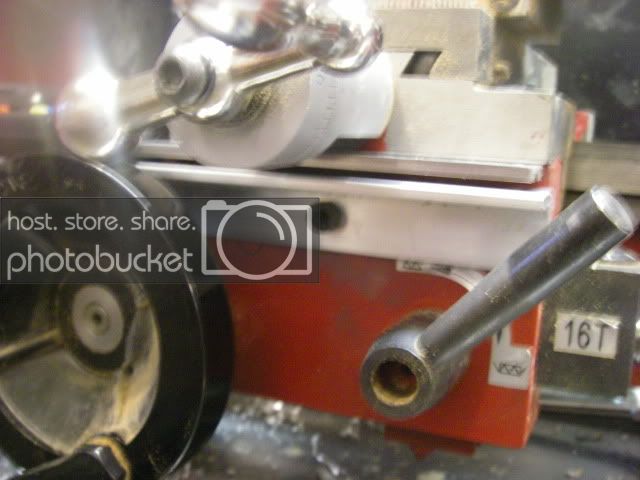

Considering how many of us drill to a specific depth I though some folks might be interested in this modification I made to my tailstock. I don't know how others do it but I used to either put a sharpie mark on the drill bit or wrapped masking tape around it. But that was tedious and not as precise as I'd would have liked.

So I got this digital scale with a remote display from Grizzly. I made a couple brackets, one for the tailstock quill, and one for the reader, and tapped a couple holes in the tailstock. It works great and it's way more accurate.

So I got this digital scale with a remote display from Grizzly. I made a couple brackets, one for the tailstock quill, and one for the reader, and tapped a couple holes in the tailstock. It works great and it's way more accurate.