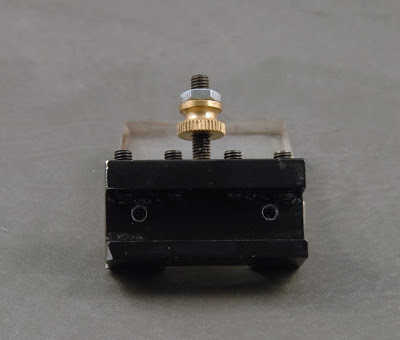

I have an A2Z QCTP (quick change tool post) I used it on my Sherline lathe and moved it onto my Atlas lathe when I switched over. The problem I had noticed on my Sherline is much more prominent on my Atlas. There is quite a bit of slop between the fit of the two. The dynamics of the system keeps you from being able to count on repeat-ability on switching back and forth between different tools. However the bad part was when making a fairly light cut on the Sherline and a moderate one on the Atlas you can watch the tool tip move backwards as it engages the material your trying to cut. The problem is there are to many variables in the holders and its not the wedge type but a single piston that the holders can rock around on.

I decided to try and fix some if not most of that problem. I took all my tool holders and drilled two holes in them. They are centered and set in from the edges to make contact on the tool post but not the dovetail part. I drilled them and tapped the holes for an 8-32 thread.

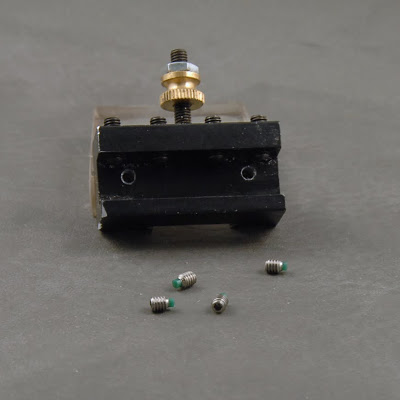

I bought some green nylon tipped 8-32 set screws to use from Ebay.

I installed the screws making them fairly even in the amount they were sticking out and then adjusted them on the tool post itself. Tightening each one up a little in turn, sliding the holder up and down until the set screw stopped it from moving. I then back it off an 1/8 of a turn.

This took all the slop out of the tool holder as it slides on and makes the lock up when I cam the lever over crisp and tight. The cutting tool no longer pushes back as I start to cut. This may give you some ideas of your own if your having the same problem. I have two dovetails on my tool post at 90 degrees to each other. I adjusted each holder for the specific dovetail it would be used on.

I decided to try and fix some if not most of that problem. I took all my tool holders and drilled two holes in them. They are centered and set in from the edges to make contact on the tool post but not the dovetail part. I drilled them and tapped the holes for an 8-32 thread.

I bought some green nylon tipped 8-32 set screws to use from Ebay.

I installed the screws making them fairly even in the amount they were sticking out and then adjusted them on the tool post itself. Tightening each one up a little in turn, sliding the holder up and down until the set screw stopped it from moving. I then back it off an 1/8 of a turn.

This took all the slop out of the tool holder as it slides on and makes the lock up when I cam the lever over crisp and tight. The cutting tool no longer pushes back as I start to cut. This may give you some ideas of your own if your having the same problem. I have two dovetails on my tool post at 90 degrees to each other. I adjusted each holder for the specific dovetail it would be used on.