You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor burnt up in 7x10 central

- Thread starter farmer

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Little machine shop is one place to go for replacement parts, tooling, and accessories. I've been very happy with my purchases from them. There is great advice on the site as well. I hope you get it spinning soon. I have had one over a year and love it. I've pulled my motor to work on squaring the headstock and it was easy to do.

Danny

Danny

SteveG

Member

Sorry for the 'smoke'.

On my 7" lathe, there is a caution to turn the speed control to zero, PRIOR to turning the switch on. Could that have been the cause? If not familiar with the unit, it would seem normal to just flip the switch on (without checking the speed control).

On my 7" lathe, there is a caution to turn the speed control to zero, PRIOR to turning the switch on. Could that have been the cause? If not familiar with the unit, it would seem normal to just flip the switch on (without checking the speed control).

Burnt up

It had been running for about a minute at 20 rpm .

I didn't know about the speed switch .

The motor isn't very big for a 3/4 HP motor

Sorry for the 'smoke'.

On my 7" lathe, there is a caution to turn the speed control to zero, PRIOR to turning the switch on. Could that have been the cause? If not familiar with the unit, it would seem normal to just flip the switch on (without checking the speed control).

It had been running for about a minute at 20 rpm .

I didn't know about the speed switch .

The motor isn't very big for a 3/4 HP motor

Last edited:

Thanks

They have the motor I need , I am going to tear this motor down and see what failed .

How is your lathe for power ?

If you had to buy a new motor would you try to put a stronger or better motor in ..?

I have had the thought of retro fitting in a same hp motor but one that is a little bigger in size or even a 1 hp motor .

Little machine shop is one place to go for replacement parts, tooling, and accessories. I've been very happy with my purchases from them. There is great advice on the site as well. I hope you get it spinning soon. I have had one over a year and love it. I've pulled my motor to work on squaring the headstock and it was easy to do.

Danny

They have the motor I need , I am going to tear this motor down and see what failed .

How is your lathe for power ?

If you had to buy a new motor would you try to put a stronger or better motor in ..?

I have had the thought of retro fitting in a same hp motor but one that is a little bigger in size or even a 1 hp motor .

If you go with a bigger motor you will overload the speed control circuit board. The new motor has to be comparable with the speed control. I'm not sure if it's a DC motor, I suspect, or a 3 phase AC motor. Little machine shop does have an upgrade kit but if I remember right it ain't cheap. There might be dust/dirt in the motor that a good cleaning might fix. There may also be brushes that need replacement ( not sure ). More HP would be nice but mine has plenty of HP for pens and smaller jobs. I've turned up to 2" aluminum without issue and 3/4" hardened stainless steel. You just can't take aggressive cuts.

Danny

Danny

Last edited:

If you go with a bigger motor you will overload the speed control circuit board. The new motor has to be comparable with the speed control. I'm not sure if it's a DC motor, I suspect, or a 3 phase AC motor. Little machine shop does have an upgrade kit but if I remember right it ain't cheap. There might be dust/dirt in the motor that a good cleaning might fix. There may also be brushes that need replacement ( not sure ). More HP would be nice but mine has plenty of HP for pens and smaller jobs. I've turned up to 2" aluminum without issue and 3/4" hardened stainless steel. You just can't take aggressive cuts.

Danny

Thanks Danny for the info

It is a 3/4 hp DC motor and it about 2/3 of the size of my 1/2 hp dc motors I have on some of my other lathes .

In other words the size of that motor doesn't impress me.

And there is zero room to put a bigger motor inless I hang one on the out side and I might have to install idler pulley's to keep the main belt from rubbing against the housing .

I don't want to replace a part that is known for failing with another one that most likely will fail .

I also don't want a lathe that cant function under a normal load if I can help it .

Seeing I will already MOST LIKELY have to buy a motor should I try to retro fit in a bigger and better motor ?

If I have to install a new control panel or box so be it

I have checked both brushes in the motor they look new .

But motor doesn't turn over right by hand .

As I rotate the motor there are stiff spots.

Motor smells burnt , I don't want to tear down the motor until my friend looks at it.

Rick_G

Member

I have checked both brushes in the motor they look new .

But motor doesn't turn over right by hand .

As I rotate the motor there are stiff spots.

Motor smells burnt , I don't want to tear down the motor until my friend looks at it.

Sounds like the bearings are shot. Likely overheated and seized then burnt the windings. Best to just put the new motor in and keep an eye on the bearings in it from now on. If they start to get rough they can be replaced with better quality bearings.

Word of caution in increasing the power and torque: Gears are plastic, head bearings are ball bearings not tapered thrust bearings, limits of the toothed belt, ETC. If you upgrade the entire system you might be looking at a bigger investment than buying a larger lathe. I would check the headstock alignment to the bed and assure myself the bed is straight along it's length. Look for wear in the cross and compound slides, tight and smooth, before investing too much in drive upgrades. The control board runs more than the motor, check it too. There are some good web pages dedicated to these little lathes (Sieg C2/C3 lathes) with great information on modifying and adjusting them. It has been very helpful for me in getting better accuracy and performance from mine for little money, just sweat and time.

http://www.mini-lathe.com/mini_lathe/reviews/sieg_sc2/sc2.htm

I've been running mine for about 18 months with the only failures being the power switch and the speed control potentiometer and a couple fuses. Maybe $15 in parts. I turn Aluminum, Brass, Stainless Steel, Acrylic, Wood, and Tru-Stone. I probably turn 8-12 hours a week. I've been able to turn threads both Imperial and Metric including making specialty tread taps for fountain pen nibs (JOWO & Bock).

Tooling cost is a different discussion. You really need the Quick Change Tool Post A2Z for Little Machine Shop (LMS). I started with carbide insert cutters (bits) but now prefer hand ground (on my belt sander) HSS. That is until this week trying to turn SS Damascus that came hardened not annealed. The cheaper carbide cutters are cutting right through it with 0.010" depth cuts with no stalling. I've only stalled the lathe with original motor drilling when I "stuck" a hot drill bit both in metal but mostly in acrylic. And the one time I crashed the cutter into the chuck (don't ask). In each case the lathe tripped off before causing any damage to the motor or control board.

I have made some mods specific for Pen turning I can send if your interested.

Danny

http://www.mini-lathe.com/mini_lathe/reviews/sieg_sc2/sc2.htm

I've been running mine for about 18 months with the only failures being the power switch and the speed control potentiometer and a couple fuses. Maybe $15 in parts. I turn Aluminum, Brass, Stainless Steel, Acrylic, Wood, and Tru-Stone. I probably turn 8-12 hours a week. I've been able to turn threads both Imperial and Metric including making specialty tread taps for fountain pen nibs (JOWO & Bock).

Tooling cost is a different discussion. You really need the Quick Change Tool Post A2Z for Little Machine Shop (LMS). I started with carbide insert cutters (bits) but now prefer hand ground (on my belt sander) HSS. That is until this week trying to turn SS Damascus that came hardened not annealed. The cheaper carbide cutters are cutting right through it with 0.010" depth cuts with no stalling. I've only stalled the lathe with original motor drilling when I "stuck" a hot drill bit both in metal but mostly in acrylic. And the one time I crashed the cutter into the chuck (don't ask). In each case the lathe tripped off before causing any damage to the motor or control board.

I have made some mods specific for Pen turning I can send if your interested.

Danny

Last edited:

motor

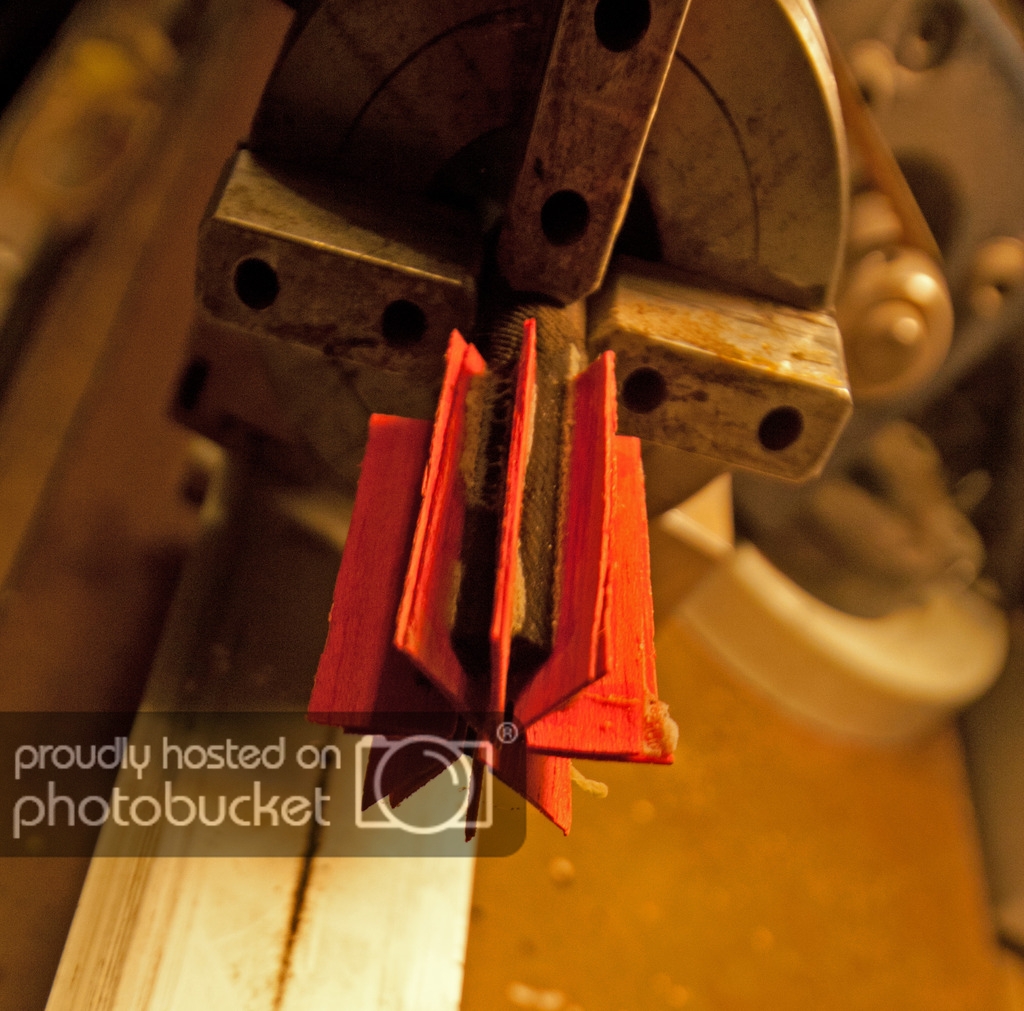

Motor had metal filling in it ,

Motor looked new inside

Armature is rubbing against one side of the fields .

two of the wave or spring washers were ant one end of the armature.

I have to wonder if someone else hasn't torn this motor apart and got the wave washer on one end of if it was a factory screw up.

Motor is still barley rubbing on one side .

Hooked DC motor to car battery an the motor does rotate but it sounds like a piston engine turning over .

Thinking of chucking up motor in another lathe and rotating it for a few hrs .

then cleaning the metal out of it and hooking it up .

Everything on the lathe looks new .. but the lathe was dirty with metal filling .

Motor had metal filling in it ,

Motor looked new inside

Armature is rubbing against one side of the fields .

two of the wave or spring washers were ant one end of the armature.

I have to wonder if someone else hasn't torn this motor apart and got the wave washer on one end of if it was a factory screw up.

Motor is still barley rubbing on one side .

Hooked DC motor to car battery an the motor does rotate but it sounds like a piston engine turning over .

Thinking of chucking up motor in another lathe and rotating it for a few hrs .

then cleaning the metal out of it and hooking it up .

Everything on the lathe looks new .. but the lathe was dirty with metal filling .

If you upgrade the entire system you might be looking at a bigger investment than buying a larger lathe.

Danny

Hi Danny

I am spoiled with lathes

Long story short my ex employer son threw me the keys to his machine shop after his father passed away.

He really didn't want to run the business and he doesn't want to sale the machine shop or most of the heavy equipment .

He also doesn't want those lathes gears rusting up and like the fact they get rotated .

3 large metal lathes and a bridge port mill .

One of the lathe is Mazak Hercules SE 2010 metal lathe

I believe its 100 inches between centers 25 hp motor 20 in swing

4 inch spindle bore .

Its really a nice lathe ...

Honestly I am trying to get away from the bigger lathes.

Right now I own 4 lathes and a large CNC router table 3 axis but I have a lathe mounted on the cnc to do tapers on pool cues .

Last edited:

If you upgrade the entire system you might be looking at a bigger investment than buying a larger lathe.

Danny

Hi Danny

I am spoiled with lathes

Long story short my ex employer son threw me the keys to his machine shop after his father passed away.

He really didn't want to run the business and he doesn't want to sale the machine shop or most of the heavy equipment .

He also doesn't want those lathes gears rusting up and like the fact they get rotated .

3 large metal lathes and a bridge port mill .

One of the lathe is Mazak Hercules SE 2010 metal lathe

I believe its 100 inches between centers 25 hp motor 20 in swing

4 inch spindle bore .

Its really a nice lathe ...

Honestly I am trying to get away from the bigger lathes.

Right now I own 4 lathes and a large CNC router table 3 axis but I have a lathe mounted on the cnc to do tapers on pool cues .

I'm unworthy. (He says as he bows to the ground) what a lucky man. There was an Ingersol Rand shop nearby auctioning off their equipment last month and I had no way to pick up the Bridgeport I was craving. They looked brand new. The two went for $800 each. Broke my heart. I learned years ago on Southbend lathes and Bridgeports. The little C2 was my reintroduction after 30 years. Originally bought to make small parts for my custom knives and folders. I need the mill for making autos. Pens have taken over my hobby time since getting the lathe.

Good to have an expert on the forum for advice.

Danny

No expert

Danny , I am not a expert or even a machinist.

I worked for Cummins engine company or for Cummins distributor ship as a field service mechanic Mining Division .

Or worked for the gold mines as a specialist on Hitachi shovels .

I was the shovel god .

https://www.youtube.com/watch?v=8n2Pkf3LO-c

If you upgrade the entire system you might be looking at a bigger investment than buying a larger lathe.

Danny

Hi Danny

I am spoiled with lathes

Long story short my ex employer son threw me the keys to his machine shop after his father passed away.

He really didn't want to run the business and he doesn't want to sale the machine shop or most of the heavy equipment .

He also doesn't want those lathes gears rusting up and like the fact they get rotated .

3 large metal lathes and a bridge port mill .

One of the lathe is Mazak Hercules SE 2010 metal lathe

I believe its 100 inches between centers 25 hp motor 20 in swing

4 inch spindle bore .

Its really a nice lathe ...

Honestly I am trying to get away from the bigger lathes.

Right now I own 4 lathes and a large CNC router table 3 axis but I have a lathe mounted on the cnc to do tapers on pool cues .

I'm unworthy. (He says as he bows to the ground) what a lucky man. There was an Ingersol Rand shop nearby auctioning off their equipment last month and I had no way to pick up the Bridgeport I was craving. They looked brand new. The two went for $800 each. Broke my heart. I learned years ago on Southbend lathes and Bridgeports. The little C2 was my reintroduction after 30 years. Originally bought to make small parts for my custom knives and folders. I need the mill for making autos. Pens have taken over my hobby time since getting the lathe.

Good to have an expert on the forum for advice.

Danny

Danny , I am not a expert or even a machinist.

I worked for Cummins engine company or for Cummins distributor ship as a field service mechanic Mining Division .

Or worked for the gold mines as a specialist on Hitachi shovels .

I was the shovel god .

https://www.youtube.com/watch?v=8n2Pkf3LO-c

If you upgrade the entire system you might be looking at a bigger investment than buying

I believe its 100 inches between centers 25 hp motor 20 in swing

4 inch spindle bore .

Its really a nice lathe ...

.

How cool would it be to have a picture of a pen turning on a 20" x 100" 25 HP lathe.

Danny

The three big lathes

If you upgrade the entire system you might be looking at a bigger investment than buying

I believe its 100 inches between centers 25 hp motor 20 in swing

4 inch spindle bore .

Its really a nice lathe ...

.

How cool would it be to have a picture of a pen turning on a 20" x 100" 25 HP lathe.

Danny

All of the big lathes are covered in oil , you cant go into the machine shop without getting oil on you some where .

You cant tough any of the tools .

Machine shop is worthless for wood .....

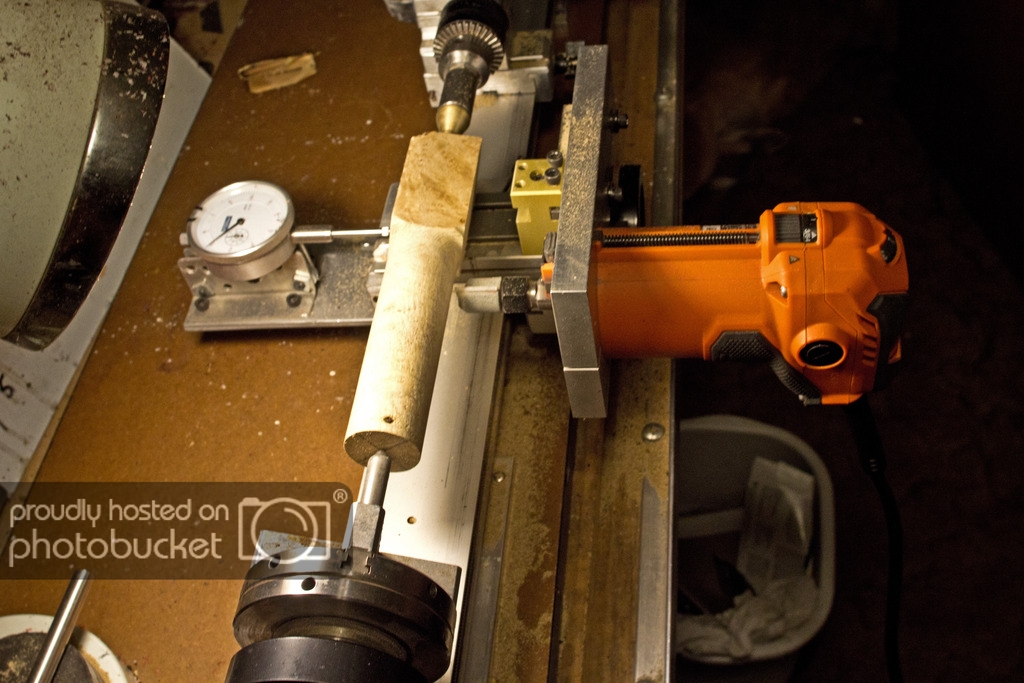

In my wood shop I now have 4 lathes 3 of them are like this except with live cutters mounted on the tool post.

Large bore headstock

When the smoke got out of my original motor a number of years ago I replaced it with a (real) 3/4 HP motor from a treadmill and hooked it up by using a jackshaft in place of the original motor and a poly V belt to hook to the jackshaft with Poly V pulleys to step down RPM on the much higher RPM of a treadmill motor.

The original controller won't handle this much real HP so I went with a Cycletrol 150 controller (you can find them fairly cheap on Ebay if you are patient).

This makes the little 7x machines a serious metal cutter, I also upped my bed length to (currently) a 16 inch bed in several steps as longer beds became available, something I highly recommend.

I think the original motor is actually somewhere around a quarter or possibly a third horsepower, certainly not the three quarters that is claimed for them.

The original controller won't handle this much real HP so I went with a Cycletrol 150 controller (you can find them fairly cheap on Ebay if you are patient).

This makes the little 7x machines a serious metal cutter, I also upped my bed length to (currently) a 16 inch bed in several steps as longer beds became available, something I highly recommend.

I think the original motor is actually somewhere around a quarter or possibly a third horsepower, certainly not the three quarters that is claimed for them.

motor

I got the original motor running , if I have to replace the motor I consider retrofitting in a bigger one .

Thank you for the info .

I have to agree the bed is short ,

When the smoke got out of my original motor a number of years ago I replaced it with a (real) 3/4 HP motor from a treadmill and hooked it up by using a jackshaft in place of the original motor and a poly V belt to hook to the jackshaft with Poly V pulleys to step down RPM on the much higher RPM of a treadmill motor.

The original controller won't handle this much real HP so I went with a Cycletrol 150 controller (you can find them fairly cheap on Ebay if you are patient).

This makes the little 7x machines a serious metal cutter, I also upped my bed length to (currently) a 16 inch bed in several steps as longer beds became available, something I highly recommend.

I think the original motor is actually somewhere around a quarter or possibly a third horsepower, certainly not the three quarters that is claimed for them.

I got the original motor running , if I have to replace the motor I consider retrofitting in a bigger one .

Thank you for the info .

I have to agree the bed is short ,

KBs Pensnmore

Member

frank123;1881807 I got the original motor running said:I looked at this on my 7 X 12, I got hold of a 3 phase motor and VFD drive to give a variable speed. The motor was almost as large as the whole lathe, the original motor (one of 3) I stripped down to the shaft and bearings and made a bracket that takes place of the motor which actually became a lay shaft, with the intentions of mounting the motor behind the lathe, but had to give the lathe back, so everything came to a stand still.

There is no room to fit a larger motor there,

Kryn

Last edited:

Lathe motor

I agree a lay shaft or jack shaft would need to be installedfrank123;1881807 I got the original motor running said:I looked at this on my 7 X 12, I got hold of a 3 phase motor and VFD drive to give a variable speed. The motor was almost as large as the whole lathe, the original motor (one of 3) I stripped down to the shaft and bearings and made a bracket that takes place of the motor which actually became a lay shaft, with the intentions of mounting the motor behind the lathe, but had to give the lathe back, so everything came to a stand still.

There is no room to fit a larger motor there,

Kryn