You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metal lathe trivia

- Thread starter farmer

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

SteveG

Member

Replicate itself.

Where is my prize? :biggrin:

Where is my prize? :biggrin:

Artisan iron designs

Member

A metal is the only known machine that can __________ _______ < two words <

Build itself

Curly

Member

Offset the tailstock.

Use the compound.

Make a tool rest to fit the compound and turn as you would with a wood lathe with chisels.

Use the compound.

Make a tool rest to fit the compound and turn as you would with a wood lathe with chisels.

Artisan iron designs

Member

There are two ways of doing a straight Taper on wood in a metal lathe .

One is to use a taper bar.

The other is ??????????

depending on your lathe and size of taper...

use the taper attachment and disconnect the cross slide nut or for a slight tapper offset the tailstock

Anglesachse

Member

There are two ways of doing a straight Taper on wood in a metal lathe .

One is to use a taper bar.

The other is ??????????

I do a taper on the butt of a pool cue without using a taper bar ....

Straight Taper... Sorry, sounds to me like a paradox. Can you clear me up on this?

The best method, for *short* tapers, is to lock the saddle and adjust the compound axial feed direction to give the desired angle.

Tool movement is by means of the axial compound screw. . To get good accuracy and a smooth cut you need the gibs to be properly adjusted.

To get an accurate taper angle using the tailstock offset method is difficult. . Good accuracy and fine adjustment can be achieved by mounting a boring head on the tailstock. . Tool movement is by the main axial feed. . Both of these "tailstock" methods require a universal drive coupler in the headstock because the workpiece axis does not align with the lathebed axis. . However the angle achievable is still small.

To do significantly large taper angles (or "long" tapers) still requires a taper bar.

(I offer these remarks tentatively and would appreciate feedback because I would like to learn to do long, "large" angle tapers.)

Tool movement is by means of the axial compound screw. . To get good accuracy and a smooth cut you need the gibs to be properly adjusted.

To get an accurate taper angle using the tailstock offset method is difficult. . Good accuracy and fine adjustment can be achieved by mounting a boring head on the tailstock. . Tool movement is by the main axial feed. . Both of these "tailstock" methods require a universal drive coupler in the headstock because the workpiece axis does not align with the lathebed axis. . However the angle achievable is still small.

To do significantly large taper angles (or "long" tapers) still requires a taper bar.

(I offer these remarks tentatively and would appreciate feedback because I would like to learn to do long, "large" angle tapers.)

Last edited:

I cheat

This will not work on steel .............

Poor boys way of tapering wood without a taper bar.

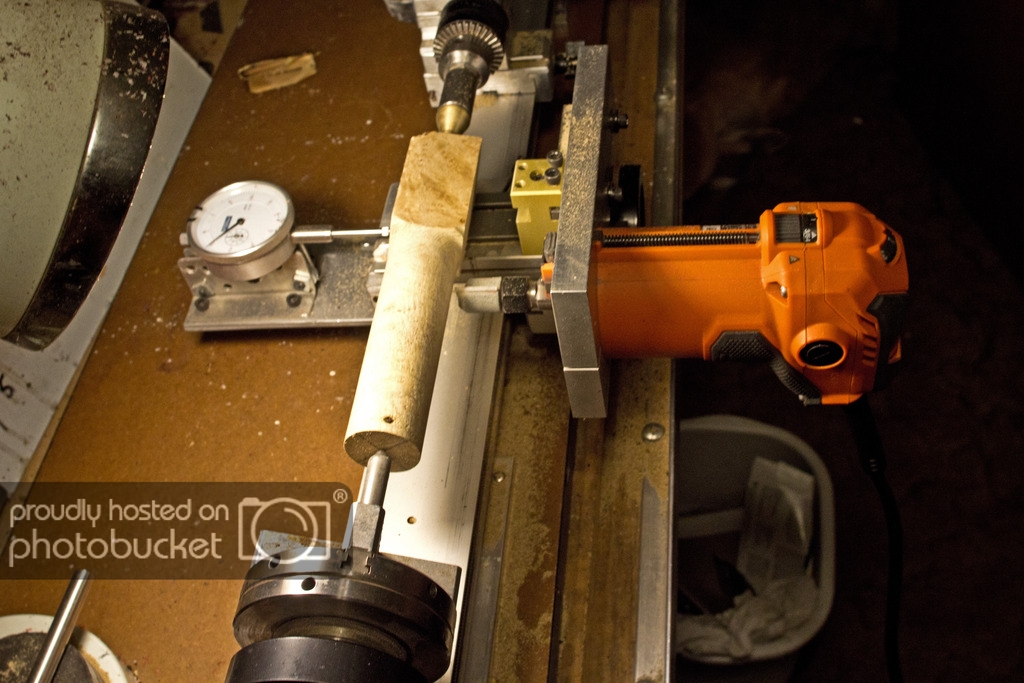

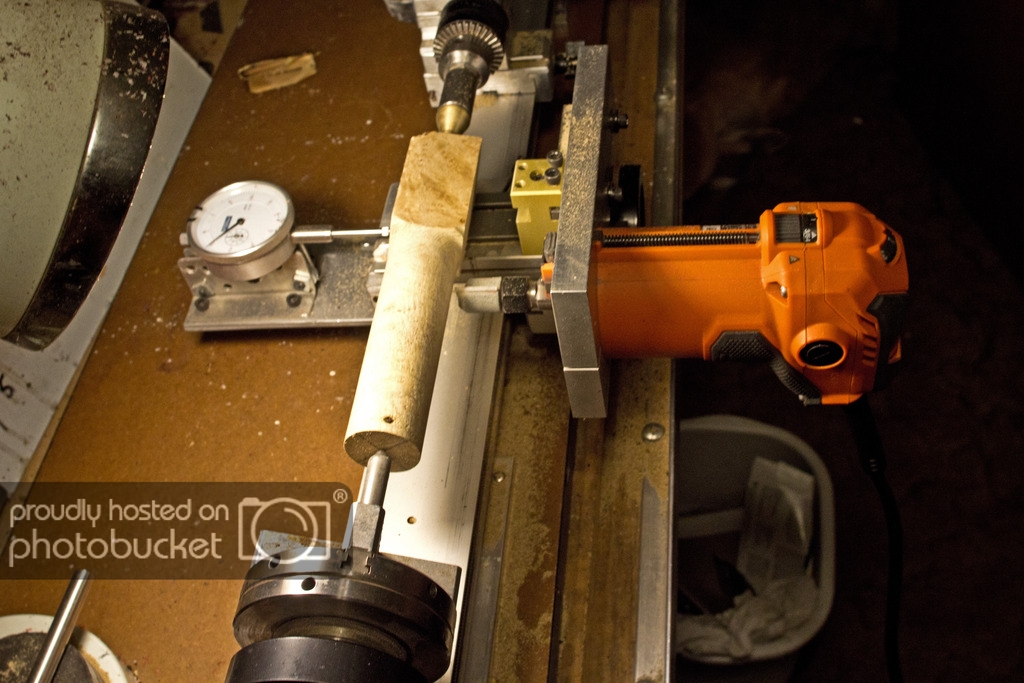

I am turning between centers , Dead center in the lathe spindle 4 jaw chuck

And a live center in the tail stock.

I bought a extra tail stock adjusted to 0.200 to one side .

Cutting 0.850 one end 1.250 on the other some times 30 inches in length.

Most tail stocks are not made to be adjusted to the side for tapering .

I use a Ridgid veneer trimmer mounted on the tool post using a router bit

or a 1/4 end mill bit in the router too.

You don't have to get the wood between centers super clamped down as in putting stress into the piece of wood , the veneer trimmers is doing ALL of the cutting and not the lathes rotation <<<<<<<<<<<<

I don't have a photo but you want the wood hitting the side of the cutter not the end for the smoothest cut .

You want to use the auto feed, for any reason you pause or stop the feed the cutter will leave a ghost mark in the wood and its impossible to get out without cutting more wood off.

The best is a taper bar , but they have these too.

https://www.cuesmith.com/off-setting-live-center-2-or-3-morse-taper.html

I am not tapering in this photo but shows basic set up .

My CNC is down right now , as soon as its up I will be using it to cut my tapers.

This will not work on steel .............

Poor boys way of tapering wood without a taper bar.

I am turning between centers , Dead center in the lathe spindle 4 jaw chuck

And a live center in the tail stock.

I bought a extra tail stock adjusted to 0.200 to one side .

Cutting 0.850 one end 1.250 on the other some times 30 inches in length.

Most tail stocks are not made to be adjusted to the side for tapering .

I use a Ridgid veneer trimmer mounted on the tool post using a router bit

or a 1/4 end mill bit in the router too.

You don't have to get the wood between centers super clamped down as in putting stress into the piece of wood , the veneer trimmers is doing ALL of the cutting and not the lathes rotation <<<<<<<<<<<<

I don't have a photo but you want the wood hitting the side of the cutter not the end for the smoothest cut .

You want to use the auto feed, for any reason you pause or stop the feed the cutter will leave a ghost mark in the wood and its impossible to get out without cutting more wood off.

The best is a taper bar , but they have these too.

https://www.cuesmith.com/off-setting-live-center-2-or-3-morse-taper.html

I am not tapering in this photo but shows basic set up .

My CNC is down right now , as soon as its up I will be using it to cut my tapers.

Last edited:

You are 100 % correct

I do mainly two maybe three tapers .

I use a compound taper on pool cue shafts 4 angles .

I the butt, its tapered and I refer to it as a straight taper which there is no such thing .

Third taper is a Parabolic and I am not sure if I can properly explain it .

There are two ways of doing a straight Taper on wood in a metal lathe .

One is to use a taper bar.

The other is ??????????

I do a taper on the butt of a pool cue without using a taper bar ....

Straight Taper... Sorry, sounds to me like a paradox. Can you clear me up on this?

I do mainly two maybe three tapers .

I use a compound taper on pool cue shafts 4 angles .

I the butt, its tapered and I refer to it as a straight taper which there is no such thing .

Third taper is a Parabolic and I am not sure if I can properly explain it .

duncsuss

Member

Straight Taper... Sorry, sounds to me like a paradox. Can you clear me up on this?

My understanding of it is this: you can put a straight-edge against the taper and there will be no gaps.

(In other words, the cut is a straight line that is not parallel to the lathe axis.)