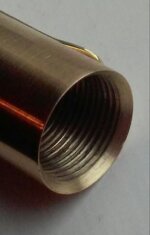

I needed a tap for a Bock 5 mm triple nib unit and didn't want to spend $40-$50. So I chucked up some 3/8" drill rod (W1) and turned it down to 0.253" and cut threads at a 0.6 metric pitch. Heated with a MAPP torch until it was no longer magnetic and quenched in water. I then ground a taper on the tip every 90 degrees. Works great in aluminum, brass, 304 SS, acrylic, and ebonite. Worked so well I made 8.5mm x 0.6, 9mm x 0.75, and 11mm x 0.75. Those worked for aluminum and brass but struggled in the 304 SS. Also much stronger than traditional taps with most of the cross-section milled away.

Attachments

Last edited: