Texatdurango

Member

There are plenty of members out there who are looking at lathes trying to figure out what to buy and with the variety and types of machines available; it's really a mind boggling, often gut wrenching process and by no means an easy one-step shopping decision.

With helping those members in mind, I think it might be beneficial if those of us who already have metal lathes would share a few things about them, both the good and the bad along with a few things we have learned along the way. Something a bit more meaningful than…. "I would recommend a 7 x 12" or "Go with brand xxx", so, I'll start………

Two years ago I decided on a Grizzly 9 x 19 lathe based mostly on what I could glean from manufacturers websites, and those aren't always the best sources, sort of like asking a car salesman who carries the best car! Basically I like the machine, it has done everything I needed it to do so far but that is because I realize its limitations when I am planning a task.

Likes….

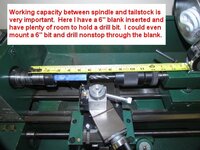

Bed Capacity…. For pen making, I like the idea of being able to chuck a 6" long, 3/4" blank into a collet chuck then chuck a drill bit (either jobber length or screw machine length) into a Jacobs or tool free drill chuck and not worry about having enough room to work. The photo below shows this setup with room to spare (I call it elbow room)

Ease of use…. Once I learned to read the 30 page manual that came with it THEN re-read it again, I found that everything was straight forward and easy to use. I also learned that THREADING, while easy now, was NOT easy at first, either to understand or initiate.

Threading…. If you plan on doing a lot of threading, make sure the machine you choose can cut the threads you will be using a lot! Having a machine that will "Cut 8 metric threads" is meaningless unless you know what pitches they are. This lathe cuts what I use a lot! Check out the photo below, notice in the mm section, I can cut .5mm, .7mm, .7.mm, .8mm, and 1mm pitches which are all pitches you will use when making pens and other fine threaded items.

Dislikes….

Tool availability…. Having a small lathe (Yes, the 9 x 19 is considered a small or "hobby" lathe) I learned that most tool companies like Shars, Enco, McMaster, etc do not carry a lot of tools for the smaller lathes. I found a nice "quick change tool post" then found that the only place I could order extra tool holders to fit my tool post was from that same company since most lathes use much larger tool posts and tool holders. I have a ½" maximum tool holding capacity and you'll find that most tool holders are ¾" and larger.

Tailstock…. In the tailstock photo below you will see a wrench left on the tensioning nut. I loved the idea of moving the tailstock on my wood lathes then pressing a lever to tighten them. With this lathe I have to loosen then re-tighten the nut every time I want to move the tailstock… It's a real pain!

Controls…. The nut on my crosslide handle is responsible for removing more skin that all other parts of the lathe combined. I'm sure better quality machines have better handles!

Threading…. In order to change from one metric pitch to another I need to remove the side panel, remove a particular gear and replace it with another gear then clean the grease off my hands before continuing. My next lathe will accomplish this by moving dials on the front of the lathe not greasy gears.

Wrapping it up, my lathe would be an adequate choice if one were on a budget if you can put up with the little annoyances and aren't in a big hurry to do some small tasks It takes up little more bench space than my Jet mini lathe and is light enough not to require a really stout bench.

Feel free to ask anything about my lathe or the tools that I use with it.

Anyone else care to share their experiences and a few details they find unique with their machines?

With helping those members in mind, I think it might be beneficial if those of us who already have metal lathes would share a few things about them, both the good and the bad along with a few things we have learned along the way. Something a bit more meaningful than…. "I would recommend a 7 x 12" or "Go with brand xxx", so, I'll start………

Two years ago I decided on a Grizzly 9 x 19 lathe based mostly on what I could glean from manufacturers websites, and those aren't always the best sources, sort of like asking a car salesman who carries the best car! Basically I like the machine, it has done everything I needed it to do so far but that is because I realize its limitations when I am planning a task.

Likes….

Bed Capacity…. For pen making, I like the idea of being able to chuck a 6" long, 3/4" blank into a collet chuck then chuck a drill bit (either jobber length or screw machine length) into a Jacobs or tool free drill chuck and not worry about having enough room to work. The photo below shows this setup with room to spare (I call it elbow room)

Ease of use…. Once I learned to read the 30 page manual that came with it THEN re-read it again, I found that everything was straight forward and easy to use. I also learned that THREADING, while easy now, was NOT easy at first, either to understand or initiate.

Threading…. If you plan on doing a lot of threading, make sure the machine you choose can cut the threads you will be using a lot! Having a machine that will "Cut 8 metric threads" is meaningless unless you know what pitches they are. This lathe cuts what I use a lot! Check out the photo below, notice in the mm section, I can cut .5mm, .7mm, .7.mm, .8mm, and 1mm pitches which are all pitches you will use when making pens and other fine threaded items.

Dislikes….

Tool availability…. Having a small lathe (Yes, the 9 x 19 is considered a small or "hobby" lathe) I learned that most tool companies like Shars, Enco, McMaster, etc do not carry a lot of tools for the smaller lathes. I found a nice "quick change tool post" then found that the only place I could order extra tool holders to fit my tool post was from that same company since most lathes use much larger tool posts and tool holders. I have a ½" maximum tool holding capacity and you'll find that most tool holders are ¾" and larger.

Tailstock…. In the tailstock photo below you will see a wrench left on the tensioning nut. I loved the idea of moving the tailstock on my wood lathes then pressing a lever to tighten them. With this lathe I have to loosen then re-tighten the nut every time I want to move the tailstock… It's a real pain!

Controls…. The nut on my crosslide handle is responsible for removing more skin that all other parts of the lathe combined. I'm sure better quality machines have better handles!

Threading…. In order to change from one metric pitch to another I need to remove the side panel, remove a particular gear and replace it with another gear then clean the grease off my hands before continuing. My next lathe will accomplish this by moving dials on the front of the lathe not greasy gears.

Wrapping it up, my lathe would be an adequate choice if one were on a budget if you can put up with the little annoyances and aren't in a big hurry to do some small tasks It takes up little more bench space than my Jet mini lathe and is light enough not to require a really stout bench.

Feel free to ask anything about my lathe or the tools that I use with it.

Anyone else care to share their experiences and a few details they find unique with their machines?

Attachments

Last edited: