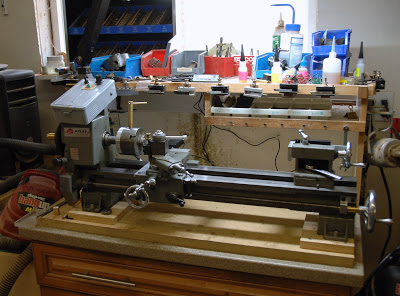

Among the other things I have been involved with, I picked up this Atlas lathe off Ebay. Its a MK2 3950 6 x 18 built around the 80s. I picked it up for $370.00 shipped but it didnt have a motor, gears or a 3 jaw chuck. It did have a 4 jaw Chuck. It is in perfect shape. I was very lucky that it is as tight as it is. It has seldom been used and well taken care of. I immediately bought the change gear set, and a MT2 to 3/4- 16 adapter for the spindle. I already had a motor from a Spectra Light CNC center I had bought and parted out.

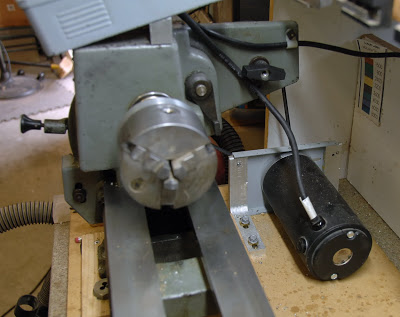

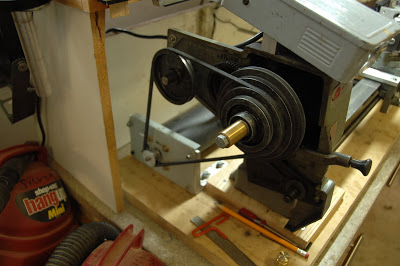

Its an AC/DC 5000 rpm 1/2hp motor. I made the aluminum motor mounts and bolted the old mounting plate and motor to them.

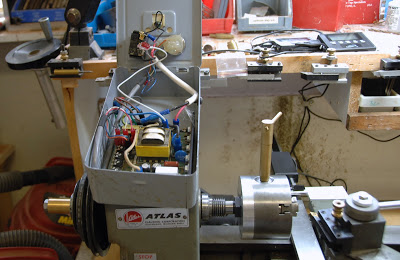

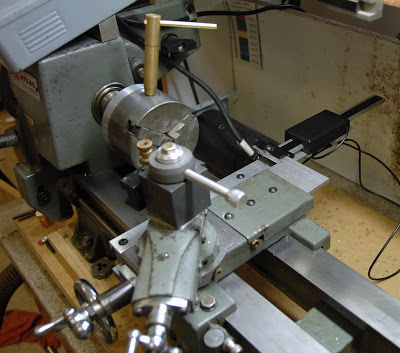

I used an old drill index box I gutted out to house the electronics and mounted it on the spindle housing. I added a green power light to it so I can easily see the power is on if the lathe is just turned down and not spinning. Like it is now in the picture.

I had a spare Qtcp and I made a t-nut to fit where the Lantern style tool post went to adapt to it. I added Dro scales to the saddle the cross slide and the tails tock. I made the tail stock up at home but took the lathe up to Mike Rouxs to drill the saddle on his larger mill for the aluminum bracket, and to get his input on placement etc. I think we had of us working on lathes that day at Mikes and Marshall Was making a pen.

I cut a wrench in 1/2 for the tail stock, a 1/4 turn locks/unlocks it.

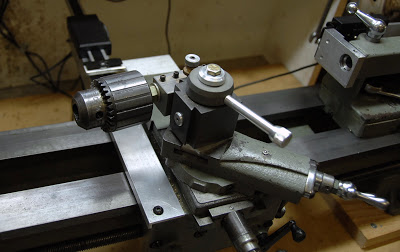

I also took the original lead screw support off and made a new one in aluminum with a bronze oilite bushing. Drilled an oil hole and mounted an extra hand wheel I bought to match on the end. I can quickly run the saddle in and lock the half nuts, use the hand wheel for fine cutting and then quickly back it out.

The tail stock on this lathe has a very short throw length. Its total travel is 1 1/4 inch (32mm) Not good fro drilling deep holes in pen blanks. So I took an extra Jacobs chuck and mounted it on a QCTP tool holder and now I can drill to my hearts content. I have drilled up to 1/2 holes now but I do it incrementally. I may get brave and see how tough it is. Maybe not.

I'm in the process of making a hand wheel to fit on the brass spacer in the front to be able to engage the gears and hand turn the lathe for threading. It does have light Metric capability. Mostly I use .75mm pitch. I need to make or find a metal chip tray. I also have to make a plastic cover for the cross slide DRO scale to protect it from swarf. So far I'm very happy with the lathe It has exceeded my expectations and is a joy to work with. I turned a piece of brass using the Beal collet holder as my test piece and the Dial indicator I didnt move more than .0005 when I checked it. I then flipped the cut end into the Bison 3 jaw chuck and did a test cut. It did move somewhere between .005 and .001 . i have an original 3 jaw 4 inch chuck on its way for larger less precise projects but Im good to go as it is. I wont get rid of my Sherline lathes I have one I have converted to cnc and I will part out the other one. I will use the 24 inch bed to mount a 4th axis set up on and mount it on my CNC Mill when I need it.

thanks for looking comments quips questions are all welcome

Its an AC/DC 5000 rpm 1/2hp motor. I made the aluminum motor mounts and bolted the old mounting plate and motor to them.

I used an old drill index box I gutted out to house the electronics and mounted it on the spindle housing. I added a green power light to it so I can easily see the power is on if the lathe is just turned down and not spinning. Like it is now in the picture.

I had a spare Qtcp and I made a t-nut to fit where the Lantern style tool post went to adapt to it. I added Dro scales to the saddle the cross slide and the tails tock. I made the tail stock up at home but took the lathe up to Mike Rouxs to drill the saddle on his larger mill for the aluminum bracket, and to get his input on placement etc. I think we had of us working on lathes that day at Mikes and Marshall Was making a pen.

I cut a wrench in 1/2 for the tail stock, a 1/4 turn locks/unlocks it.

I also took the original lead screw support off and made a new one in aluminum with a bronze oilite bushing. Drilled an oil hole and mounted an extra hand wheel I bought to match on the end. I can quickly run the saddle in and lock the half nuts, use the hand wheel for fine cutting and then quickly back it out.

The tail stock on this lathe has a very short throw length. Its total travel is 1 1/4 inch (32mm) Not good fro drilling deep holes in pen blanks. So I took an extra Jacobs chuck and mounted it on a QCTP tool holder and now I can drill to my hearts content. I have drilled up to 1/2 holes now but I do it incrementally. I may get brave and see how tough it is. Maybe not.

I'm in the process of making a hand wheel to fit on the brass spacer in the front to be able to engage the gears and hand turn the lathe for threading. It does have light Metric capability. Mostly I use .75mm pitch. I need to make or find a metal chip tray. I also have to make a plastic cover for the cross slide DRO scale to protect it from swarf. So far I'm very happy with the lathe It has exceeded my expectations and is a joy to work with. I turned a piece of brass using the Beal collet holder as my test piece and the Dial indicator I didnt move more than .0005 when I checked it. I then flipped the cut end into the Bison 3 jaw chuck and did a test cut. It did move somewhere between .005 and .001 . i have an original 3 jaw 4 inch chuck on its way for larger less precise projects but Im good to go as it is. I wont get rid of my Sherline lathes I have one I have converted to cnc and I will part out the other one. I will use the 24 inch bed to mount a 4th axis set up on and mount it on my CNC Mill when I need it.

thanks for looking comments quips questions are all welcome