wizard

Member

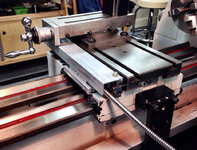

Hmmm.. Not sure quite how to start this... let me see. I got this lathe..yep.. from Chris Wood at LMS. It's a 8.5 X 20...I decided to install a DRO that I had purchased from DROPROS. Well, my installation didn't start out as planned. But the end, I had the DRO's installed with the extra features of seven very inaccurately placed, carefully drilled, meticulously tapped holes with smooth clean threads each filled with a very nice black socket head screw. At some point.... I thought it might be a good idea to get help as I was starting to like the satisfying feeling of drilling, tapping and screwing in bolts for the heck of it. So...before I turned my lathe into a pin cushion, I got help from a very talented engineer, Shawn AKA The Penguin. He came over and got me started on the right track, placed and adjusted the carriage scale...and gave me enough confidence to finish the installation. Thanks so much Shawn! I got tips along the way from Chris Wood at LMS and Todd at DROPROS. I put a few pictures here and the rest in my members photo album if you want to take a look. I had to modify several of the brackets and the scale covers using a mini mill. Doc