Today I made a new tool post power tool holder. It works great and I'm pretty pleased with it. :biggrin:

I then decided to try a new way to make Pool Cue Blanks. Up till now, I've used a Heath Robinson flexi joint that worked but was a pain as the blank had to be glued to it.

This new one is a highly modified socket 'universal' swivel joint. The main problem with these is that they aren't true universals as the two axis' need to be the same. It was tough to alter this one!! It has a threaded end thet screws into a 4 jaw scroll chuck. A boring head in the tailstock creates the offset.

I then just took a couple of pics of some of the attachments that I use the most on my lathe.

When folks ask about which ML to buy, I always advocate a bigger one.

I couldn't do half the stuff I do on a smaller lathe.

I think the pics are self explanitary, but please feel free to ask anything :wink:

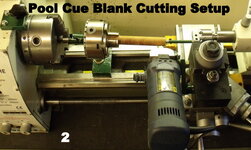

I then decided to try a new way to make Pool Cue Blanks. Up till now, I've used a Heath Robinson flexi joint that worked but was a pain as the blank had to be glued to it.

This new one is a highly modified socket 'universal' swivel joint. The main problem with these is that they aren't true universals as the two axis' need to be the same. It was tough to alter this one!! It has a threaded end thet screws into a 4 jaw scroll chuck. A boring head in the tailstock creates the offset.

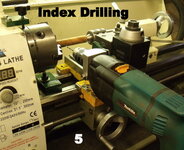

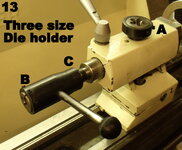

I then just took a couple of pics of some of the attachments that I use the most on my lathe.

When folks ask about which ML to buy, I always advocate a bigger one.

I couldn't do half the stuff I do on a smaller lathe.

I think the pics are self explanitary, but please feel free to ask anything :wink:

Attachments

-

1Holder.jpg135.9 KB · Views: 630

1Holder.jpg135.9 KB · Views: 630 -

2PoolCue.jpg165.1 KB · Views: 875

2PoolCue.jpg165.1 KB · Views: 875 -

3Wave.jpg171 KB · Views: 569

3Wave.jpg171 KB · Views: 569 -

4Scallop.jpg190.8 KB · Views: 596

4Scallop.jpg190.8 KB · Views: 596 -

5IndexDrill.jpg219.9 KB · Views: 566

5IndexDrill.jpg219.9 KB · Views: 566 -

6Crank.jpg177.9 KB · Views: 541

6Crank.jpg177.9 KB · Views: 541 -

7TPBallTurner.jpg184.1 KB · Views: 562

7TPBallTurner.jpg184.1 KB · Views: 562 -

8CSBallTurner.jpg179.2 KB · Views: 656

8CSBallTurner.jpg179.2 KB · Views: 656 -

9MillSlide.jpg211.2 KB · Views: 527

9MillSlide.jpg211.2 KB · Views: 527 -

10Chucks.jpg157.8 KB · Views: 461

10Chucks.jpg157.8 KB · Views: 461 -

11Flute.jpg205 KB · Views: 933

11Flute.jpg205 KB · Views: 933 -

12TapGuide.jpg163.5 KB · Views: 485

12TapGuide.jpg163.5 KB · Views: 485 -

13DieHolder.jpg194 KB · Views: 549

13DieHolder.jpg194 KB · Views: 549