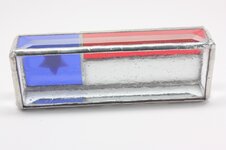

That's foil. You can't use lead came on exteriors, just the zinc window braces/brackets.

I'ld prefer a design that had a "window" for viewing of the box contents. Say, placing a beveled "diamond" shape in the top center.

This design uses 2 color elements. The orange represents the base color of the box, while the red represents the beveled diamond shape clear glass insert for the "window" into the box.

Lead came (pronounced almost like cane, and in fact is a derivative of the same word meaning a 6 foot length of a material, such as wood, reed, or other such material... lead came was originally produced in 6-foot lengths by pouring it into molds made of cane) is made to have a shaped cross-section that looks like an H with rounded sides. The 2 pieces of glass butt up against the middle of the H and provide stability and rigidity. Taking one piece of glass away would result in instability and weakness... so it's not made to go round the edges of a piece or for use in 3-D stained glass art, like a box. To made the edges stronger, a flat piece of zinc was tinned and bent into a U channel, to fit round the edges of the work and then it was soldered to the lead lines all around the edges.

Copper Foil methods for stained glass developed recently, only in the past hundred years or so. The copper foil was adhered to the glass in several different methods for many years, only recently was the extremely easy to use copper tape developed. The copper tape is made wide enough to just wrap round the edges of a piece of glass. The glass pieces are all laid flat so that the copper foil is adjacent to another piece of foil ... the major join lines are fluxed and soldered first, to hold it all in place while the artist then lays down smooth flowing lines of solder. The entire exterior is also tinned in the same manner. Using this method allows parts to stick OUT of the 2-D plane of structure, giving rise to 3-D stained glass art, like my dolphin, stained glass lampshades, candle holders, ect ... plus boxes like these.

My dolphin ...