Thanks for the details Georges. As i understand, you don't cut the blank round, but 'grind' it using abrasive. What exactly is that 'flap disk' tool?

I have used sanding paper instead of a gouge to turn a couple phoenix palm pens, but one problem i had is it goes out of round rather quickly - well, it was cross cut palm too. You don't run into that issue with your flap disk?

When working with very fragile materials, one step i find is very efficient is to run thin CA inside the hole, let dry, and then glue the tube with epoxy. That way, the material has been strengthened right where it matters, around the tube.

Hahahaha, I remember someone not that long ago that, put it the same way, I don't do wood turning I do wood "grinding"...!

:wink::biggrin::biggrin:

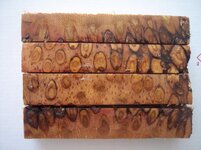

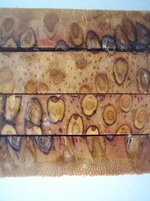

Not exactly tough, this system was developted, particularly to deal with the very difficult pen blanks materials, one come accrosss. Not always they are the soft stuff, many times, the very contrary is the case and the "Flap" discs have proven to be yoir best friend, when dealing with these type materials.

I should say that, I turn normal woods with gouges and I tent to give it a go to the very hard materials first with my carbide tipped gauges but, when I'm dealing with something that is soft from extremely fragile, I don't hesitate for a second and I grab by 4" grinders set up with various grits, to save time changed grits using a single grinder, and for the price these grinders are sold in our days $40 or less, I see no point in using only 1 when 2 different grits at least are required...!

I have been talking about the "Flap" disc for some time now, and I wrote a simple thread to explain what it is and how it works,

here

In fact, many turners have resorted on the heavy sandpaper grits to do exactly the same, most times due to the inability to use a cutting gauge to take the blank to final shape and size, regardless of what material is , taken the precautionary road with the sandpaper and this is all fine by me, one was the right to make they choices to use how and what they use to get the job done...!

However, one of the major difference of the "Flap" disc is the minimal risk of getting the blank out of round, as the hand sanding will produce quite easily...! The gentle touch, only needed to make the "Flap" discs work properly, gives a very accurate cut surface that can be improved if one uses the tool rest as a support/guide for the grinder outer disc cover.

I can also tell you that, I understand why so many people I know that have started using the "Flap" discs in their every day turnings, are so sceptical at least to admit publicly that, they are using it, as they feel that would be scrutinized/ridiculousrised by some, for using such a method that is not within the proper wood turning methodology they preach...!:wink:

Is only one thing I say to you, try it and then let me know...!

Cheers

George

:giggle:

:giggle: