qquake

Member

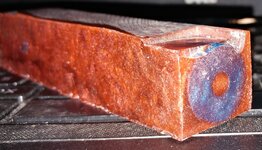

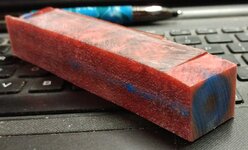

Has anyone turned a Wonder Window blank? How exactly did you do it? The instructions say to turn it "roundish" so you can see where to cut and drill it. But it's rectangular, not square, so it won't center in a chuck. Maybe a spur drive with a spring loaded point?

https://www.exoticblanks.com/Wonder-Windows-Resin-Blank-Light-Blue-and-Red.html

https://www.woodturnerscatalog.com/p/107/4396/Apprentice-Safety-Drive-Center?term=spur+drive

https://www.exoticblanks.com/Wonder-Windows-Resin-Blank-Light-Blue-and-Red.html

https://www.woodturnerscatalog.com/p/107/4396/Apprentice-Safety-Drive-Center?term=spur+drive