Simple to do if you have a table saw.

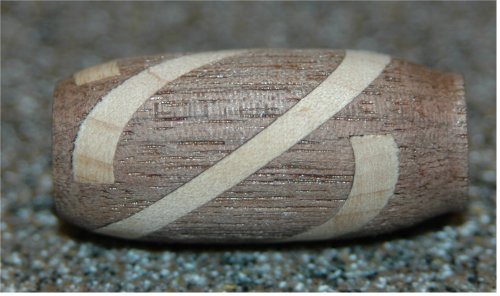

Start by ripping the inlay material to the same width as the kerf of your blade (use a good blade for best results).

Next, take a scrap piece of pine about 12-18 inches long and cross cut with the angle I want in the blank (mark the line that you want in the blank and adjust miter gauge to cut that angle on the end of the pine) and cut.

Now with miter gauge at 90 degrees to blade use the pine to hold the blank using two surface tape. Clamp a block to the rip fence and adjust the fence to the proper distance from the blade so that the blade will cut the line you are after on the blank (this step is for repeatability).

Adjust the blade to cut just a little past half way through the blank. Make the cut. I should also add that you must use a square tooth blade. An alternating tooth blade will not give you a square bottom groove.

Glue a piece of the inlay material in the kerf (I use titebond).

Trim excess on band saw.

Rotate blank 90 degrees and repeat kerf cut, glue, trim, three more times.

Turn.

I hope this makes some sense. The comments about this working on a large diameter pen may stem from the test piece I turned being short and fat. The same pattern would result on a straight barrel. The only difference is that the end of the swirl would be a little less flared.

Richard