suefox51

Member

I have the Delta 460 lathe and want to start drilling the blanks on the lathe instead of the drill press. Can someone give me a list of items I need to purchase to be able to do that???

Thanks,

Sue

Thanks,

Sue

Pretty well covered, many of the large pen kits (i.e. Emperor) do require larger than 1/2" bits so if you don't get a bigger chuck you'll need to get reduced shank bits...They are not a lot costlier than standards.I personally use the HF drill chuck mentioned by Ed, works fine for me. Here's the link: 1/2" MT2 Mini-Lathe Drill Chuck

If you do go with a 1/2inch chuck, make sure that for any larger (over 1/2inch) drill bits you get have a 1/2inch (or smaller) shank, like those at Woodcraft (e.g., Ed's example of 15mm: Buy Colt 15 mm Pen Maker Bit at Woodcraft.com

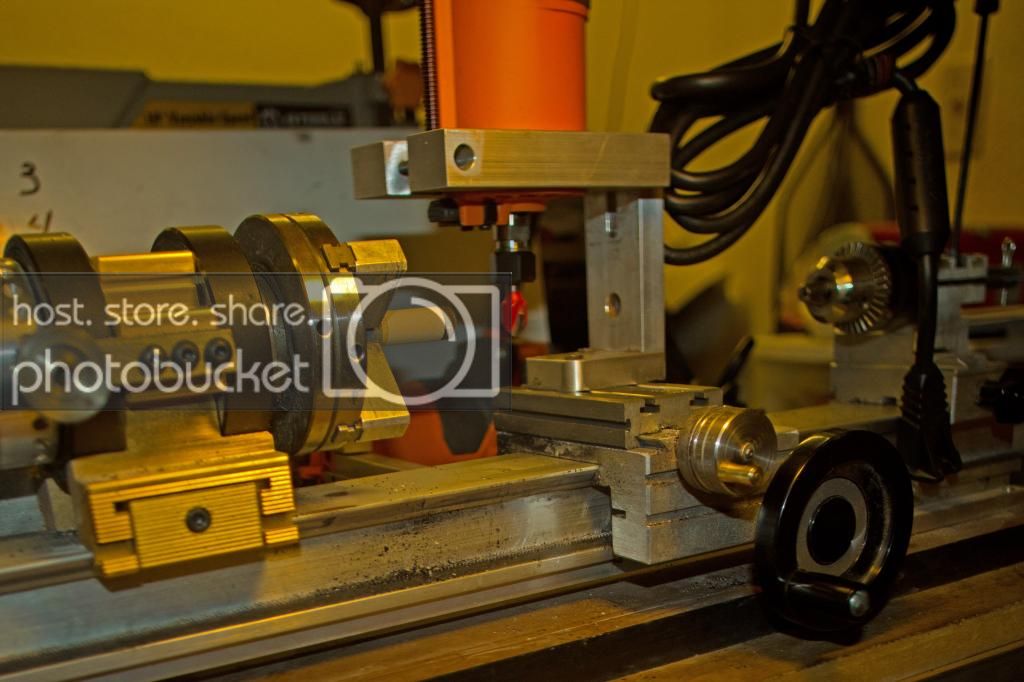

By far I would highly recommend the pen drilling chuck from PSI.

If it were me I would spend the extra money to get the larger one if you plan on doing bottle stoppers and things like that but this one is perfect.

Dedicated Pen Blank Drilling Chuck at Penn State Industries

Also I would get the 1/2" drill chuck as mentioned. Buy once.

By far I would highly recommend the pen drilling chuck from PSI.

If it were me I would spend the extra money to get the larger one if you plan on doing bottle stoppers and things like that but this one is perfect.

Dedicated Pen Blank Drilling Chuck at Penn State Industries

Also I would get the 1/2" drill chuck as mentioned. Buy once.

This is exactly what I did. It really hurt to press the process payment button, but it is worth it. I have never had a single problem drilling blanks.

Just as an FYI.

If you're blanks aren't square, you're not going to get a straight hole, ever. And it won't matter how much you spend on your chucks.

It doesn't matter much on most blanks but if you start doing segmented stuff you'll need the equipment to ensure your blanks are square before you drill them.

Thanks for the great info and links - bought the one from PSI and got 10% off since it was my "anniversary" of first order with them!

Sue

I have the Delta 460 lathe and want to start drilling the blanks on the lathe instead of the drill press. Can someone give me a list of items I need to purchase to be able to do that???

Thanks,

Sue