jrc

Member

I go for the forks, up to 3". If you cut down the middle of a fork you will see highly figured wood. Sometimes it is the easiest to collect small branches to cut up for blanks. Often I see penturners with huge chunks of wood cutting up for blanks and when ready to use, they have a bunch of plane looking wood. That happened to me many times.

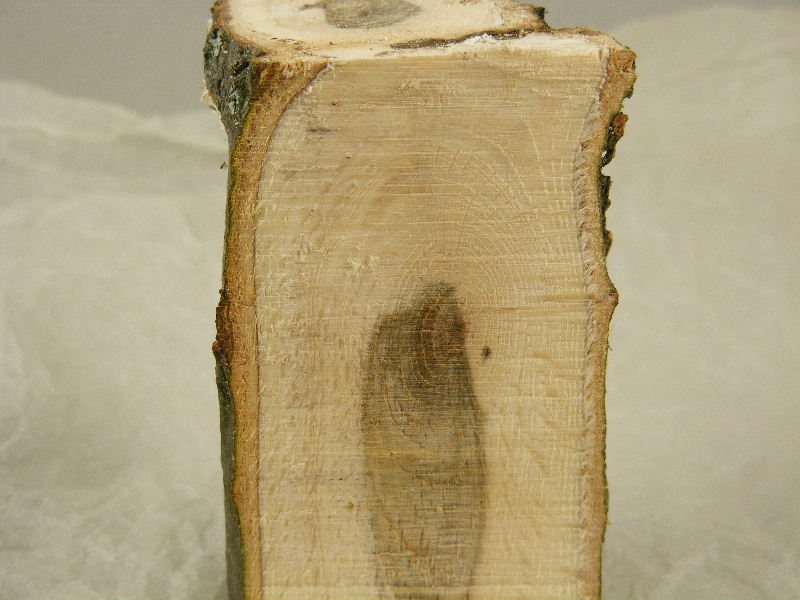

Now I sometimes use small branches up to about 2 1/2". Most of the time they have a light or white sapwood and the center or heartwood is darker. I'll drill them where they are two toned, both light and dark wood. People love the two toned pens. The photos are white oak someone cut from their camp on the lake

Now I sometimes use small branches up to about 2 1/2". Most of the time they have a light or white sapwood and the center or heartwood is darker. I'll drill them where they are two toned, both light and dark wood. People love the two toned pens. The photos are white oak someone cut from their camp on the lake