What a great collection of ideas and references!

In one's introductions to a forum, a person rarely covers all bases. I'm a former Metals teacher and wannabe engineer. I like to use that as an excuse for my exacting questions.

Dogcatcher is correct. My Shopsmith has a 5/8" spindle with a flatten side for setscrews, which are required for all attachments. I have a 1/2" drill chuck and a 'regular' drive center for lathe work. As I mentioned I have a 4 jaw chuck on the way which will help immensely.

I'm presently using a 7mm mandrel made for the Shopsmith spindle, and some of you may remember my concerns about vibration, with the resulting advice to switch to TBC.

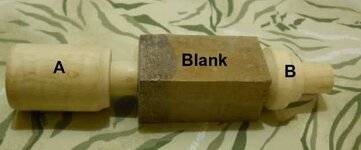

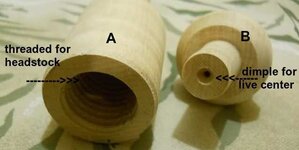

What I didn't understand is how the blanks would be held in place. From the info provided here, and some other reading I did earlier today regarding a 'mandrel saver, apparently the

application of pressure from the (in my case) quill, to the blank, ending at the live center is what holds the blank it place for turning. Is that correct?

It also seems that there are a variety of tapered point implements I could make that would also work...does that relieve one of having a bushing for every pen in creation? I have 2 new pen kits, one is the 'Princeton" which is only one piece anyway.