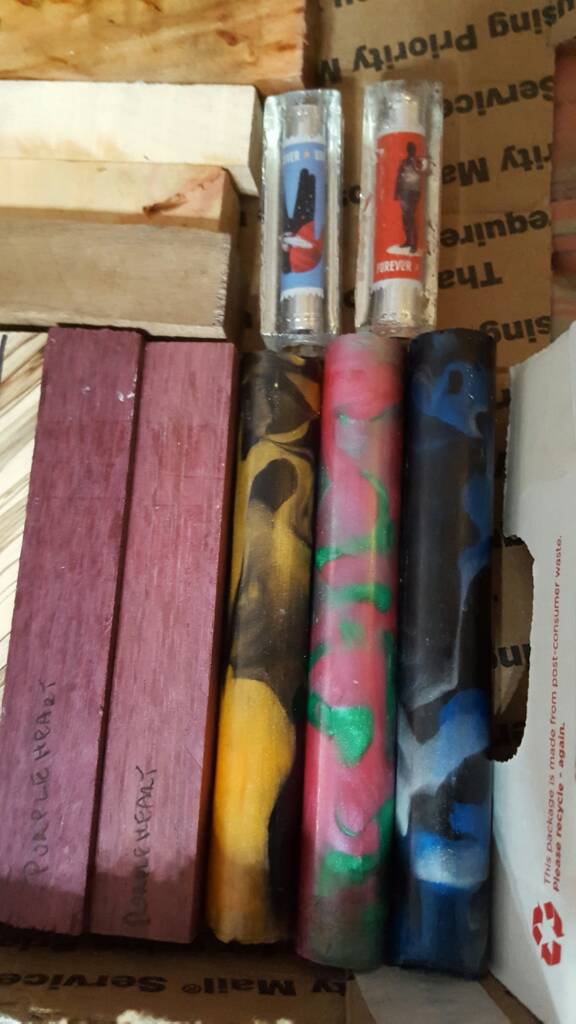

Rebecca has another question about some blanks in her prize package. What material are the pretty, round blanks? She has mostly been using an easy gouge with a carbide blade and would like to know if the HSS gouges would be better for these blanks.

She has been wanting to use the HSS gouges but needs Dad to sharpen them for her first. She hasn't learned how to do that and since they are her Grandpa's gouges doesn't want to mess them up.

Sent from my SAMSUNG-SM-G890A using Tapatalk

She has been wanting to use the HSS gouges but needs Dad to sharpen them for her first. She hasn't learned how to do that and since they are her Grandpa's gouges doesn't want to mess them up.

Sent from my SAMSUNG-SM-G890A using Tapatalk