WIDirt

Member

OK,

So I decided to try my hand at segmenting. I have had 0 luck out of 4 tries.

Here is what I was trying to do.

Using Ipe, aluminum, Snakewood. Ipe for the center 9/10, A layer of aluminum on each end, capped with Snakewood on each end. This is for a Stratus Click pen, by the way. Oh, and each attempt is with new materials. I don't feel like trying to scrape epoxy off, and then trying to line up previously attempted drilled holes.....

The Ipe that I am using is solid wood flooring from a friend, and the pen is for him. It is only 9/16" thick, so I know I'll have to be extremely careful to drill straight as this uses a 3/8" bit.

So, I cut the piece to the length I want, + a little bit. Sand it with a belt/disc sander at 80 grit to get square on each end. I figure the 80 grit will give it some grab. Clean the wood with Isopropyl alcohol. All seems good here.

Yes, I am using a Pepsi can for the aluminum. I cut it about 3/4 inch square, AFTER sanding both sides to bare aluminum, as I am aware of the coatings, both inside and out, using 400 grit to save as much aluminum as possible. I then scuff it well with 80 grit, again to get some grab. Clean the aluminum with Isopropyl alcohol. Again, all seems good here.

Snakewood is treated pretty much the same as the Ipe. Again, all seems well.

I mix up my epoxy, Locktite brand, 5 minute set, 20 minute "working" hold, 24 hour cure. Coat up the ends of the Ipe, add the aluminum, coat the aluminum, add the snakewood and clamp in the lathe. I clamp it tight enough that all is adhering, and tight, but trying to keep from clamping too tight. Left in the "clamp" overnight. Now understand, I have done this over the last week and a half.... 4 times....

OK, as soon as I start to drill, maybe 1/8" in, haven't even hit the aluminum yet, and, POOF, the snakewood lets go. Twice, I made it through the aluminum, only to have it and the snakewood pop off.

I am drilling at 500 rpm. Brad tip drill bit that is very recently purchased, but not its first pen, so I am sure it is sharp. (the cut on my finger from its first pen is still healing...) Tighten the tailstock about 1/4 turn, wait tighten again, wait, etc, etc. It takes a good three minutes to get a 1/4' deep this way... (My wife doesn't understand the heat thing... She keeps saying, if you go faster it won't get so hot.....NOT!)

So, am I drilling too fast, do you think? Am I not prepping my materials properly? Am I not ???whatevering???

Any help would be greatly appreciated! I'd really like to make this pen!

Thanks!

So I decided to try my hand at segmenting. I have had 0 luck out of 4 tries.

Here is what I was trying to do.

Using Ipe, aluminum, Snakewood. Ipe for the center 9/10, A layer of aluminum on each end, capped with Snakewood on each end. This is for a Stratus Click pen, by the way. Oh, and each attempt is with new materials. I don't feel like trying to scrape epoxy off, and then trying to line up previously attempted drilled holes.....

The Ipe that I am using is solid wood flooring from a friend, and the pen is for him. It is only 9/16" thick, so I know I'll have to be extremely careful to drill straight as this uses a 3/8" bit.

So, I cut the piece to the length I want, + a little bit. Sand it with a belt/disc sander at 80 grit to get square on each end. I figure the 80 grit will give it some grab. Clean the wood with Isopropyl alcohol. All seems good here.

Yes, I am using a Pepsi can for the aluminum. I cut it about 3/4 inch square, AFTER sanding both sides to bare aluminum, as I am aware of the coatings, both inside and out, using 400 grit to save as much aluminum as possible. I then scuff it well with 80 grit, again to get some grab. Clean the aluminum with Isopropyl alcohol. Again, all seems good here.

Snakewood is treated pretty much the same as the Ipe. Again, all seems well.

I mix up my epoxy, Locktite brand, 5 minute set, 20 minute "working" hold, 24 hour cure. Coat up the ends of the Ipe, add the aluminum, coat the aluminum, add the snakewood and clamp in the lathe. I clamp it tight enough that all is adhering, and tight, but trying to keep from clamping too tight. Left in the "clamp" overnight. Now understand, I have done this over the last week and a half.... 4 times....

OK, as soon as I start to drill, maybe 1/8" in, haven't even hit the aluminum yet, and, POOF, the snakewood lets go. Twice, I made it through the aluminum, only to have it and the snakewood pop off.

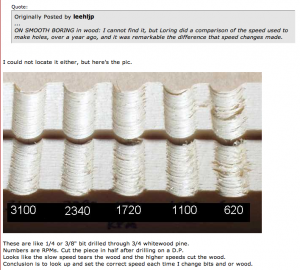

I am drilling at 500 rpm. Brad tip drill bit that is very recently purchased, but not its first pen, so I am sure it is sharp. (the cut on my finger from its first pen is still healing...) Tighten the tailstock about 1/4 turn, wait tighten again, wait, etc, etc. It takes a good three minutes to get a 1/4' deep this way... (My wife doesn't understand the heat thing... She keeps saying, if you go faster it won't get so hot.....NOT!)

So, am I drilling too fast, do you think? Am I not prepping my materials properly? Am I not ???whatevering???

Any help would be greatly appreciated! I'd really like to make this pen!

Thanks!

Last edited: