Jamesomac

Member

A Simple Solution for Squaring the End of Pen Blanks.

I looked at all the options online for squaring the ends of pen blanks, but I found that many of the jigs were not that easy to make. I don't like having to buy all the different size shafts for my pen mill, and, lets face it, the more you use it, the less sharp it becomes. I feel that sanding is a better option as long as you can sand it square in relation to the tube.

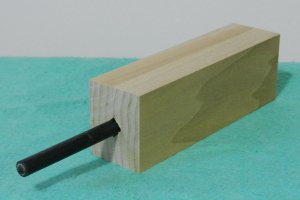

I thought that if I could use a simple block of wood with a hole or groove perfectly centered through it, that would be a great start. Drilling a perfectly straight hole through this block is impossible, at least for me, so I tossed that idea. It then occurred to me that if I could cut two pieces of wood the same size (about 5" long by 1 ½" wide by ¾" thick, and route a groove (with a V-groove router bit) the length of each piece using a router table and a fence, I could then put these pieces together and have a perfectly straight opening through the block. It doesn't have to be round; it just has to hold the rod straight and tight. And, since I already own the Disassembly Punch Set, I use these instead of bolts. It's just a matter of sliding in the bolt or punch, and letting it protrude a couple of inches into the blank. Then, tighten the two screws that hold the two pieces together, and hold the block against the mitre guide as you lightly sand the ends of the blank.

When I made my first jig, I assembled it and used this piece to test the accuracy of the mitre guide and table of the disk sander. Lightly sand the end piece, then check it both ways using a square. Make any necessary adjustment to the sander to ensure perfect squaring. Ensure that your mitre guide doesn't wobble in the channel. If it does, do your testing and squaring with the mitre guide pushed flush against the side of the channel facing the sanding disk.

The v-grooves could also be cut with a table saw, but it is a little trickier as you can cut only one side of the groove at a time.

You can make a jig for several to fit different size tubes, but it isn't really necessary as long as you hold the blank securely against one side of the rod as you square it.

I looked at all the options online for squaring the ends of pen blanks, but I found that many of the jigs were not that easy to make. I don't like having to buy all the different size shafts for my pen mill, and, lets face it, the more you use it, the less sharp it becomes. I feel that sanding is a better option as long as you can sand it square in relation to the tube.

I thought that if I could use a simple block of wood with a hole or groove perfectly centered through it, that would be a great start. Drilling a perfectly straight hole through this block is impossible, at least for me, so I tossed that idea. It then occurred to me that if I could cut two pieces of wood the same size (about 5" long by 1 ½" wide by ¾" thick, and route a groove (with a V-groove router bit) the length of each piece using a router table and a fence, I could then put these pieces together and have a perfectly straight opening through the block. It doesn't have to be round; it just has to hold the rod straight and tight. And, since I already own the Disassembly Punch Set, I use these instead of bolts. It's just a matter of sliding in the bolt or punch, and letting it protrude a couple of inches into the blank. Then, tighten the two screws that hold the two pieces together, and hold the block against the mitre guide as you lightly sand the ends of the blank.

When I made my first jig, I assembled it and used this piece to test the accuracy of the mitre guide and table of the disk sander. Lightly sand the end piece, then check it both ways using a square. Make any necessary adjustment to the sander to ensure perfect squaring. Ensure that your mitre guide doesn't wobble in the channel. If it does, do your testing and squaring with the mitre guide pushed flush against the side of the channel facing the sanding disk.

The v-grooves could also be cut with a table saw, but it is a little trickier as you can cut only one side of the groove at a time.

You can make a jig for several to fit different size tubes, but it isn't really necessary as long as you hold the blank securely against one side of the rod as you square it.