eliasbboy

Member

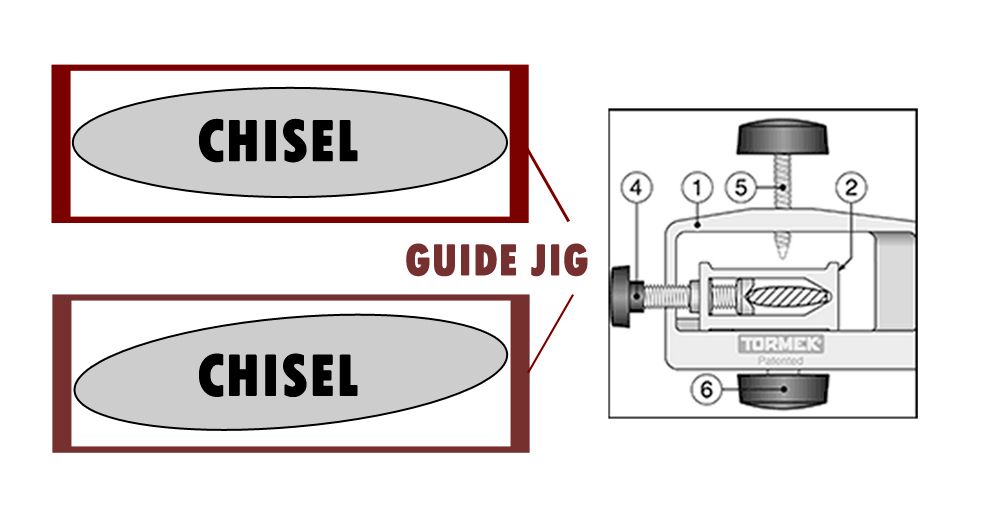

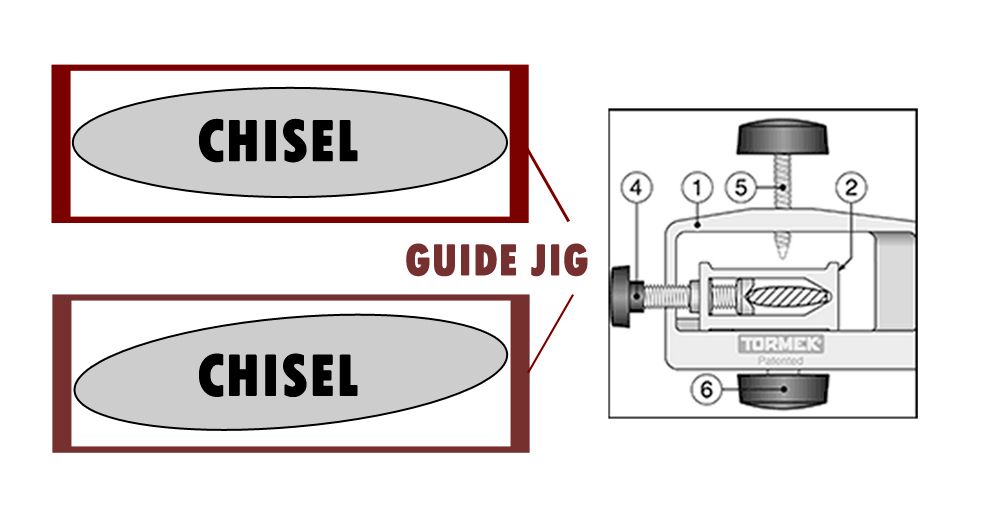

God as my witness, my level of happiness in life would grow 10 fold if I could properly sharpen my tools. It's my blind spot. My Achilles heel. I would almost pay someone to come to my house and sharpen them for me at this point. That, or sell blood and plasma to buy new tools when they dull. I have a Work Sharp, two actually, an 8 inch grinder with the Wolverine sharpening system, water stones, Veritas guides and Tormek guides, yet I STILL have the ability to make none of them work. My current lack of success revolves around the skew chisel guides. The guides clamp the skew in place to allow repeated sharpening at a constant angle. However, the geometry of the guides does not match with my oval skews. I made a picture to illustrate.

My forum attachments aren't working for some reason so I am using photobucket for the moment to host that pic. Am I over-thinking the variation that is possible in the chisel placement? When I sharpen the chisel once, I have a nice edge. If I go back to touch up or hone, and I rub a black marker on the blade to see if I have it set correctly, I am always off and now grinding a "new" edge. Any help, wisdom, or reality slap in the face would be greatly appreciated. Michael

My forum attachments aren't working for some reason so I am using photobucket for the moment to host that pic. Am I over-thinking the variation that is possible in the chisel placement? When I sharpen the chisel once, I have a nice edge. If I go back to touch up or hone, and I rub a black marker on the blade to see if I have it set correctly, I am always off and now grinding a "new" edge. Any help, wisdom, or reality slap in the face would be greatly appreciated. Michael

My forum attachments aren't working for some reason so I am using photobucket for the moment to host that pic. Am I over-thinking the variation that is possible in the chisel placement? When I sharpen the chisel once, I have a nice edge. If I go back to touch up or hone, and I rub a black marker on the blade to see if I have it set correctly, I am always off and now grinding a "new" edge. Any help, wisdom, or reality slap in the face would be greatly appreciated. Michael

My forum attachments aren't working for some reason so I am using photobucket for the moment to host that pic. Am I over-thinking the variation that is possible in the chisel placement? When I sharpen the chisel once, I have a nice edge. If I go back to touch up or hone, and I rub a black marker on the blade to see if I have it set correctly, I am always off and now grinding a "new" edge. Any help, wisdom, or reality slap in the face would be greatly appreciated. Michael