mikeschn

Member

I'll bet the answer is obvious, probably even easy... but right now it's eluding me... so please help me out.

I'm making a closed end Tycoon. I'm working on the cap. The instructions are as follows...

CAP BLANK:

• Mark the center on both ends of the blank.

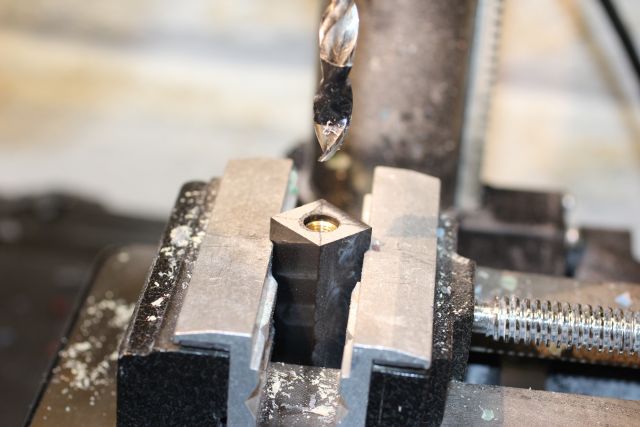

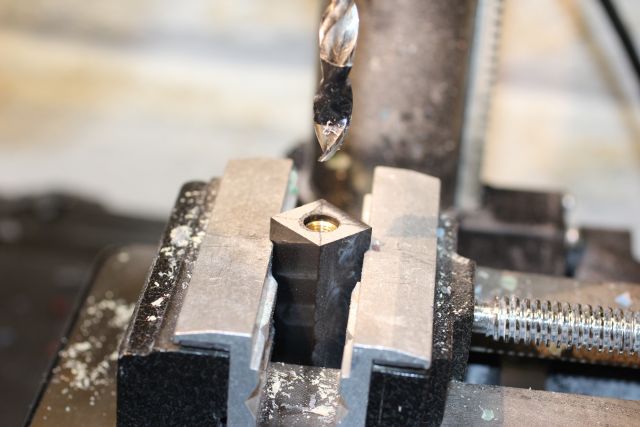

• Drill a 10mm hole at one end, 11/32" deep (Diagram B & C)

• Squeeze glue drops into the hole, slide the cap insert recessed

end in first into the hole. Let dry.

• Use a sander to square the end over the insert.

So here you see, I've drilled the hole and glued in the insert. I'm ready to use a sander to square the end.

Normally I use a barrel trimmer. Obviously that won't work, as the hole is only 11/32" deep. And the blank is not truly square, and it's not known which surfaces, if any, are truly parallel to the hole.

So how do I sand the blank perpendicular to the hole?

Mike...

I'm making a closed end Tycoon. I'm working on the cap. The instructions are as follows...

CAP BLANK:

• Mark the center on both ends of the blank.

• Drill a 10mm hole at one end, 11/32" deep (Diagram B & C)

• Squeeze glue drops into the hole, slide the cap insert recessed

end in first into the hole. Let dry.

• Use a sander to square the end over the insert.

So here you see, I've drilled the hole and glued in the insert. I'm ready to use a sander to square the end.

Normally I use a barrel trimmer. Obviously that won't work, as the hole is only 11/32" deep. And the blank is not truly square, and it's not known which surfaces, if any, are truly parallel to the hole.

So how do I sand the blank perpendicular to the hole?

Mike...