Lathe

Mike that's a really interesting looking piece of hardware... could you give a little more info?? I doubt if its store bought...

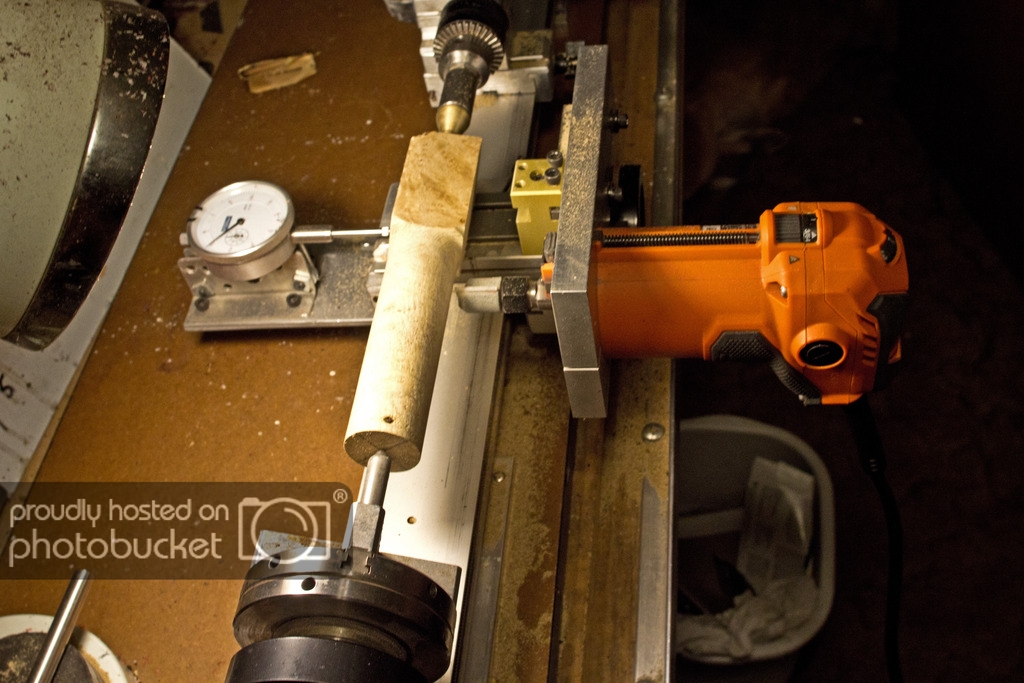

It is a cue lathe Mid American cues .

Its called his professional model with the large spindle bore and a 24 slot indexer .

It has a deco cues ridgid trimmer mount with a ridgid veneer trimmer

Todd the owner is first class,

Large bore headstock

If you are really interested in one, I can post a bunch of photos of the different ways of mounting a live cutter .

The tail stock also adjusts side to side so you can taper between centers without a taper attachment .

You can buy the models that have a auto feed and threading .

I have a total of 3 of these lathes one is mounted on my CNC

Other one I want to make a feed system for the lathe that will also cut threads ...

I like the lathe's , they are not heavy easy to move around or even take to shows .

I can make cues on mine .

You can cut point do pedals cut slotted rings buy a killing attachment and a compound cross slide .

You can buy riser blocks to raise the spindle and tail stock inches higher.

and if you notice the spindle and motor slide up and down the bed of the lathe .

Making the little lathe very able to do allot of different cuts .