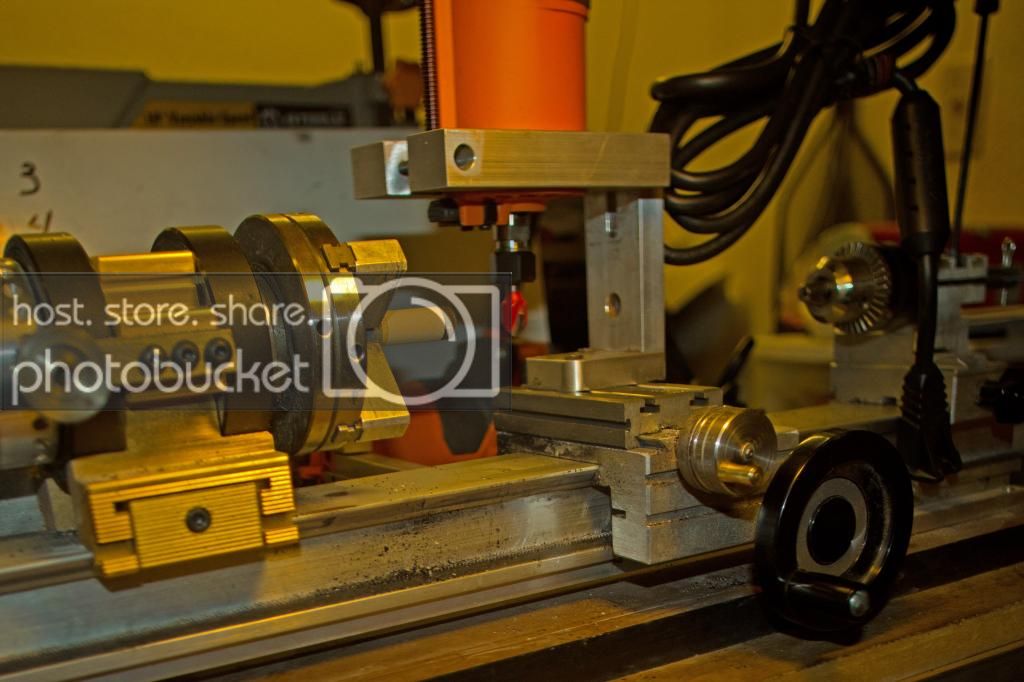

lathe

Farmer,

That's a lot of equipment and process to replace a skew. And, the skew will get a better finish, and it's WAY quieter! But to each his own.

I never thought of it as I trying to replace the skew ?

Yes it is allot of equipment and processes to turn a small piece of wood into a functioning work of art.

I was trying to explain there are different ways of doing the same thing.

Live cutter normally doesn't chip the wood but yes most of the time electric motors do make noise.

As Of the finish of the cut, yes I see your point.

All of my work is loaded with inlays, if a skew was to snag a inlay then it would tear it out.

For me and the style of work I do a skew wouldn't work for me.

For my style of work a live cutter is a must......

I was more worried about trying to come up with ways to shape the wood with out taking the chance of tearing out a piece of wood.

And under those conditions the live cutters really do a great job.

I hope you can understand how some peoples technics and styles of there workmanship can be extremely different from one another.

And it would only make sense that the tools they use or there technics would also be allot different too.

Regardless of everything said and done I don't have a problem with chipping off a piece of wood when I don't want it to, and if I make a little noise giving my self and my work the best possible chance of seceding and producing a functioning work of art , then so be it.

Being called noisy and slow really doesn't hurt my feelings as long as I am not called late for dinner :biggrin: