woodyoureally

Member

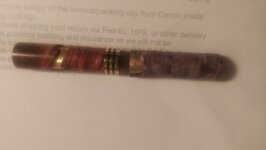

I have two stabilized/colored maple burl blanks that broke on me. The red one was during a dissasembly and the purple one was on the lathe while turning it.

I was trying to think of what I can use to fill or repair these. The purple one has more options due to being on the end and not assembled yet. I know i could cut it clean and just patch in a scrap piece to turn it down, but also curious about other options.

The red one is the one I am really thrown on. I can't get that centerband/thread out of the tube so it seems I am really limited on how I can repair/save.

Any ideas?

Thank you!

I was trying to think of what I can use to fill or repair these. The purple one has more options due to being on the end and not assembled yet. I know i could cut it clean and just patch in a scrap piece to turn it down, but also curious about other options.

The red one is the one I am really thrown on. I can't get that centerband/thread out of the tube so it seems I am really limited on how I can repair/save.

Any ideas?

Thank you!