pauly99

Member

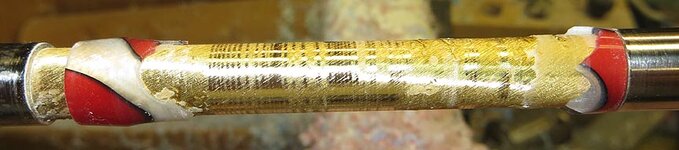

Long story short, I turned a blank out of round. I've aligned my lathe and would still like to turn the Wall Street kit I have. Is there a way to remove the tube from the blank and then possibly clean for reuse? Time is slightly limited this weekend. Otherwise I would do the couple hour drive to/from Woodcraft for some extra tubes.