ghostrider

Member

I'm not sure if this is the correct forum, so please forgive me and move to appropriate one if necessary.

I'm interested in input from those who have knowledge and experience about/with this.

I've been experimenting a lot lately with different brands, and one thing I like about Premo! is the variety of colors and effects it comes in. (I know I can mix my own with other brands, I just haven't gotten there yet). The problem I have is that it seems that no matter how long I bake it, how hot or warm I bake it, or how many times I bake it, it is still soft and rubbery. I understand that it's supposed to basically be like PVC, and that Premo! was formulated to be flexible, but is it supposed to be like this?

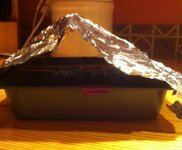

I made an awesome blank for a friend recently, and he reported that, "once he got past the outer layer, it became soft and eventually blew apart." I've got a ¾"x3/4" blank that I made (while experimenting for the SegBox) that I've baked probably five or six times minimum (I got to the point where I threw it in with every other batch of Premo! I made, and lost count). Finally, today, just to see how far things could go, I baked it at 275* for probably two hours. I also decided to not burry it in baking soda this time. Needles to say, the top side was well burnt, while the bottom part was fine. Also, on a recommendation from someone in a Yahoo! group, I used the ice water method. Even still, once it had completely cooled, it was still somewhat soft enough for me to push in and it still flexed. I broke it in two to see the inside, and it was still soft enough for me to indent with my finger nail (It did however, spring back out gradually), and I could feel it give under thumb pressure. It was easily manipulated (not hard like balsa or basswood), and I got very similar results with a Sculpey III blank (my first exposure to PC) that I actually did turn. It too was spongy enough to push in. It seems to have a memory kind of like those firm/soft insoles that Spenco used to make, but quite a bit firmer.

I've used Cernit, Kato, and Fimo, and neither of those seems to present this problem. I've peeled cured Kato off of brass tubes to find that it's so hard that without the tube it is extremely stiff and strong. I've turned Fimo, and Cernit both, also with good results (and of course some learning examples along the way).

I've managed to have at least one good set with the Premo! (a faux Paua Shell) that I was careful with (baked it about three, maybe four times), but I still wonder how well Premo! will hold up over time with this type of consistency, as well as how this sort of flexibility with affect the finish. A couple times I've just decided to give up on Premo!, but then I'll have a success like the last Cigar I made, and keep trying.

Does anyone else have experience with this brand? What are your views, and thoughts from those experiences? Is there something I can do differently to get better results?

Any insight and help will be appreciated.

David

I'm interested in input from those who have knowledge and experience about/with this.

I've been experimenting a lot lately with different brands, and one thing I like about Premo! is the variety of colors and effects it comes in. (I know I can mix my own with other brands, I just haven't gotten there yet). The problem I have is that it seems that no matter how long I bake it, how hot or warm I bake it, or how many times I bake it, it is still soft and rubbery. I understand that it's supposed to basically be like PVC, and that Premo! was formulated to be flexible, but is it supposed to be like this?

I made an awesome blank for a friend recently, and he reported that, "once he got past the outer layer, it became soft and eventually blew apart." I've got a ¾"x3/4" blank that I made (while experimenting for the SegBox) that I've baked probably five or six times minimum (I got to the point where I threw it in with every other batch of Premo! I made, and lost count). Finally, today, just to see how far things could go, I baked it at 275* for probably two hours. I also decided to not burry it in baking soda this time. Needles to say, the top side was well burnt, while the bottom part was fine. Also, on a recommendation from someone in a Yahoo! group, I used the ice water method. Even still, once it had completely cooled, it was still somewhat soft enough for me to push in and it still flexed. I broke it in two to see the inside, and it was still soft enough for me to indent with my finger nail (It did however, spring back out gradually), and I could feel it give under thumb pressure. It was easily manipulated (not hard like balsa or basswood), and I got very similar results with a Sculpey III blank (my first exposure to PC) that I actually did turn. It too was spongy enough to push in. It seems to have a memory kind of like those firm/soft insoles that Spenco used to make, but quite a bit firmer.

I've used Cernit, Kato, and Fimo, and neither of those seems to present this problem. I've peeled cured Kato off of brass tubes to find that it's so hard that without the tube it is extremely stiff and strong. I've turned Fimo, and Cernit both, also with good results (and of course some learning examples along the way).

I've managed to have at least one good set with the Premo! (a faux Paua Shell) that I was careful with (baked it about three, maybe four times), but I still wonder how well Premo! will hold up over time with this type of consistency, as well as how this sort of flexibility with affect the finish. A couple times I've just decided to give up on Premo!, but then I'll have a success like the last Cigar I made, and keep trying.

Does anyone else have experience with this brand? What are your views, and thoughts from those experiences? Is there something I can do differently to get better results?

Any insight and help will be appreciated.

David