jleiwig

Member

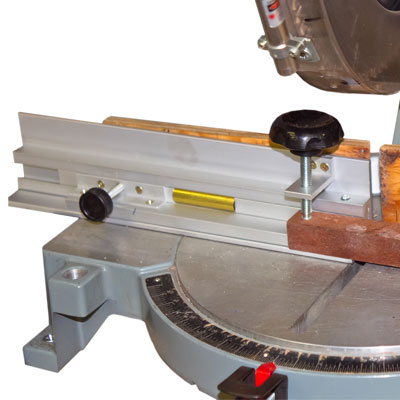

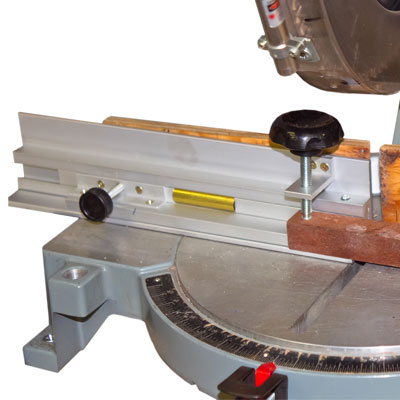

I purchased the jig shown here and it arrived last night.

I'm wondering if anyone could show me a picture of how they mounted it to their miter saw?

I was thinking of drilling throught the bottom and tapping holes in the base of the CMS for an easily removable, but accurately positioned mounting. But then I'm worried about tear out due to the space between the bottom of the blank and the ZCI on my mitersaw.

I'm wondering if anyone could show me a picture of how they mounted it to their miter saw?

I was thinking of drilling throught the bottom and tapping holes in the base of the CMS for an easily removable, but accurately positioned mounting. But then I'm worried about tear out due to the space between the bottom of the blank and the ZCI on my mitersaw.