Russknan

Member

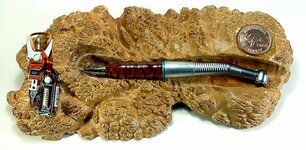

I hesitate going to the well of knowledge once again, but I'm not sure I have a problem that's solvable. I recently came into a very small quantity of ipe wood from the old Coney Island boardwalk. I have a few friends and family who would very much like to have a pen for commemoration. I cut a few blanks on the bandsaw and drilled them. This stuff is hard! Not to mention over 100 years old. Anyway, I cut one blank parallel to the grain, and two at a diagonal, thinking I might get better figure. Glued the tubes, then proceeded to use my barrel trimmer on the first Gatsby blank. Sharpened the flutes first. One side went OK but, just as I started to trim the other, the end of the blank blew apart. (See picture.) Other than using sharp tools and going slowly, is there a way to make survival of the blank a little more likely in the future (at least when trying the next diagonal)? Would it help to coat the whole thing in CA before trimming, etc.? I don't have the equipment - yet - or the knowledge to stabilize the blank, although I wondered about that. The wood is so hard, though, I doubt that much would penetrate. If I've asked too many questions lately, please tell me, in private or public. I can take it. And I'll try to wait a bit before soliciting help again. Russ

![DSCF0003 [640x480].JPG](/data/attachments/69/69335-46d147163329d8b21ad5388ff362cd00.jpg)

![DSCF0001 [].JPG](/data/attachments/69/69339-a738ed3efafb1cf7c644f21d0ba2e9bd.jpg)