stevers

Member

Hey folks'

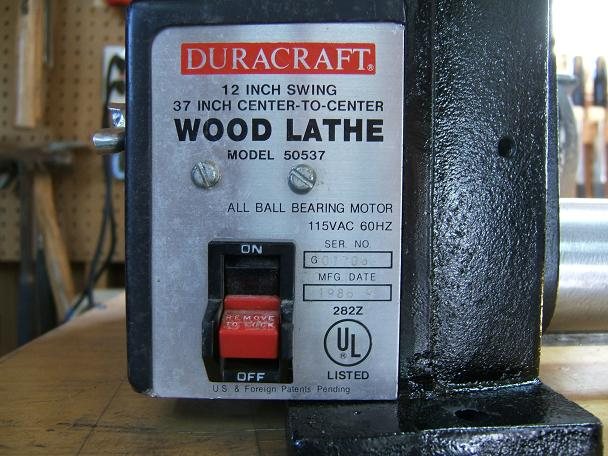

Need some help and any comments you have. Yesterday I picked up this old lathe from a guy a couple of towns over for $60.00. Did some clean up and painting. It's a Duracraft model 50537. 3/4HP iduction moter, 12" swing, 37" between centers, spindle lock and 5 speeds. 575 RPM to 3580 RPM.

I disassembled it and checked some tollerances. The rear of the spindle shaft (where the pully mounts) is within a half a thousands. I guess that would be something like 0.0005?. The front of the spindle shaft is a little harder to check accurately, seems to be within 0.002-0.003. Overall it seems to be real close to true when spinning.

One probeblem is the morse taper, it is a little bit messed up inside the shaft. Looks like someone forced the spur or tryed to pry it out. I have cleaned it up pretty good, but it will be hard to tell untill I can get a new spur or a mandrel to check the fit.

Also, can you tell me from the picture below of the spur next to the pen, if this is a #1 MT? All I have used up till now is a Jet pen lathe with the #0 MT.

Below are some picks of the lathe. Any comments or help would be greatly apreciated. Thank you for looking.

Also, what is the general opinion of the shaft design of this lathe.(where the tool rest and tais stock mount?) I wouder if flex could be a probeblem on longer turnings. I intend to bolt the hole thing down, so that should help.

Which morse taper do I have here?

Again thank you for looking and commenting and sorry for the long post. I was just hoping to get some good info.

I hope this is'nt in the wrong forum, was'nt realy sure where to put it.

Need some help and any comments you have. Yesterday I picked up this old lathe from a guy a couple of towns over for $60.00. Did some clean up and painting. It's a Duracraft model 50537. 3/4HP iduction moter, 12" swing, 37" between centers, spindle lock and 5 speeds. 575 RPM to 3580 RPM.

I disassembled it and checked some tollerances. The rear of the spindle shaft (where the pully mounts) is within a half a thousands. I guess that would be something like 0.0005?. The front of the spindle shaft is a little harder to check accurately, seems to be within 0.002-0.003. Overall it seems to be real close to true when spinning.

One probeblem is the morse taper, it is a little bit messed up inside the shaft. Looks like someone forced the spur or tryed to pry it out. I have cleaned it up pretty good, but it will be hard to tell untill I can get a new spur or a mandrel to check the fit.

Also, can you tell me from the picture below of the spur next to the pen, if this is a #1 MT? All I have used up till now is a Jet pen lathe with the #0 MT.

Below are some picks of the lathe. Any comments or help would be greatly apreciated. Thank you for looking.

Also, what is the general opinion of the shaft design of this lathe.(where the tool rest and tais stock mount?) I wouder if flex could be a probeblem on longer turnings. I intend to bolt the hole thing down, so that should help.

Which morse taper do I have here?

Again thank you for looking and commenting and sorry for the long post. I was just hoping to get some good info.

I hope this is'nt in the wrong forum, was'nt realy sure where to put it.