acturbo

Member

Hey everyone,

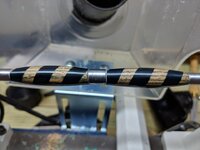

I've been making pens for about a year on and off. I have not problems turning pens casting blanks or any other aspect, but I just can't seem to get a scratch free finish on acrylics or alumilite. I've looked at all the videos, read all the threads, tried higher lathe speeds, lower lathe speeds, starting with a higher grit, starting with a lower grit, less pressure, more pressure, and I just can't get a finish I'm happy with. I attached a couple of photos of the pen I'm working on at the moment, it has been dry sanded starting at 320 grit to 400 to 600 to 1000 to 1500, then wet sanded from 1500 up to 3600. I know already at this point if I keep going the scratches will certainly not come out.

Does anyone have the magic tip I'm looking for? Any help would be greatly appreciated.

Thanks,

Chris

https://photos.app.goo.gl/VERRvtUivmmKDivC3

https://photos.app.goo.gl/rzwAZcKg0CwH9oXa2

I've been making pens for about a year on and off. I have not problems turning pens casting blanks or any other aspect, but I just can't seem to get a scratch free finish on acrylics or alumilite. I've looked at all the videos, read all the threads, tried higher lathe speeds, lower lathe speeds, starting with a higher grit, starting with a lower grit, less pressure, more pressure, and I just can't get a finish I'm happy with. I attached a couple of photos of the pen I'm working on at the moment, it has been dry sanded starting at 320 grit to 400 to 600 to 1000 to 1500, then wet sanded from 1500 up to 3600. I know already at this point if I keep going the scratches will certainly not come out.

Does anyone have the magic tip I'm looking for? Any help would be greatly appreciated.

Thanks,

Chris

https://photos.app.goo.gl/VERRvtUivmmKDivC3

https://photos.app.goo.gl/rzwAZcKg0CwH9oXa2

Last edited: