Was wondering if anyone has any helpful suggestions on drilling pencil cob corn for slimlines. I have some pencil cobs but the 7 mm bit is blowing them to pieces. Was wondering if there is a drilling technique that would work without stabilizing or if there is a kit that would use a smaller bit size. I have made cigars out of larger cobs but wanted to make slimlines. Cobs make great looking pens and I believe the smaller pen will sell better that the larger heavy pen. Thanks in advance for any suggestions.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pencil Cob Corn Drilling

- Thread starter Pett8

- Start date

Signed-In Members Don't See This Ad

- Status

- Not open for further replies.

Signed-In Members Don't See This Ad

leehljp

Member Liaison

Without stabilizing them, you will need a VERY sharp bit. Some people will probably disagree, the the higher speed will cut through better than slow speed. Slow speed will allow a bit to catch, tear and shred the fibers, which will lead to a blowout. Since you will not have a lot of heat build up in a corn cob, it won't hurt to run the drill at the highest speeds.

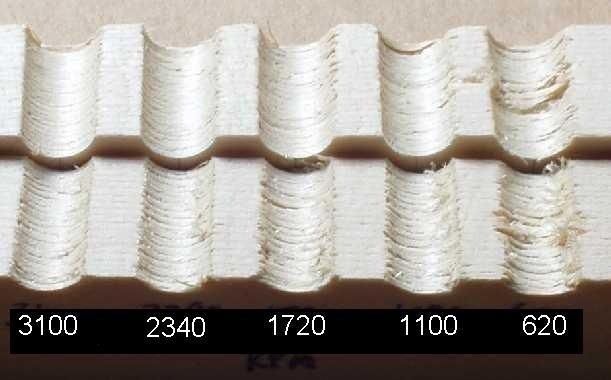

Below is a picture of soft white pine and several drill bit speeds using the same bit. Notice how the slower speed tears the fibers. Tearing on the soft corn cob will lead to blowouts.

I would also look for ways to stabilize the wood, such as soaking in thinned polyurethane for a day or two and then letting it dry for several days. Any way to harden it will help in drilling and turning.

Also bear in mind that most of the time that most people do these, they do them by putting in the work that aids in making them - stabilizing.

Below is a picture of soft white pine and several drill bit speeds using the same bit. Notice how the slower speed tears the fibers. Tearing on the soft corn cob will lead to blowouts.

I would also look for ways to stabilize the wood, such as soaking in thinned polyurethane for a day or two and then letting it dry for several days. Any way to harden it will help in drilling and turning.

Also bear in mind that most of the time that most people do these, they do them by putting in the work that aids in making them - stabilizing.

papaturner

Member

Pett8, I have done several slimline pens with the pencil cob corn cob.It can be done but stablizing is a must.I stablized mine by soaking with ca glue. I suggest this be done outside due to the fumes(they`re rough). Good luck!

Perry

Perry

rhahnfl

Member

I've cut a bunch and pre-drilled them. I plan on trying to stabilize them with a mix of 1/2 polyuerthane and 1/2 thinner. I want to get my pressure pot going so I can pull a vacuum on them. I've heard that that mix dries fairly quickly.

low_48

Member

I bought a piece of 1/4" brass tubing at the hardware store and sharpened the inside of the tube with a countersink tool. Chuck it in the drill press (carefully because you can crush the tube if you tighten too much) and drill away. Cuts like a dream. After about 4 drillings you have to take out the tube and clean out the compress cob, core material. If the cob is pretty small diameter, you may have to follow with a drill bit, but not usually. The tube will not cut out the hard material, just the soft white. Leaves a completely clean bore, no blowout, no stabilizing needed.

- Status

- Not open for further replies.