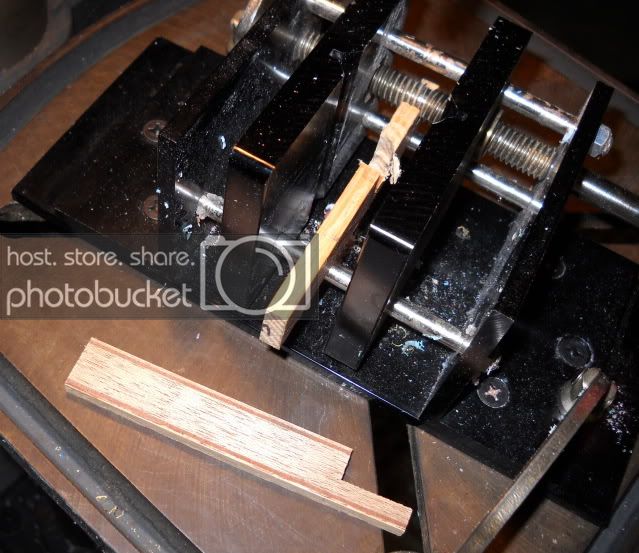

Okay I bought this

http://www.leevalley.com/wood/page.aspx?c=1&p=54855&cat=1,41659

self centering pen drilling vise.

I hand tighten the wood blank in the vise, start drilling and some harder woods take a bit for the drill to bite and drill down but while its drilling downwards the wood blank seems to slip downwards. I have to open it up and and re-adjust the wood blank upwards then continue to drill. Some wood blanks seem to I dunno push the vise apart alittle maybe. Causing the red handle impossible to turn back without the aid of a pair of pliers.

What do I do? or shall I just get a better vise?

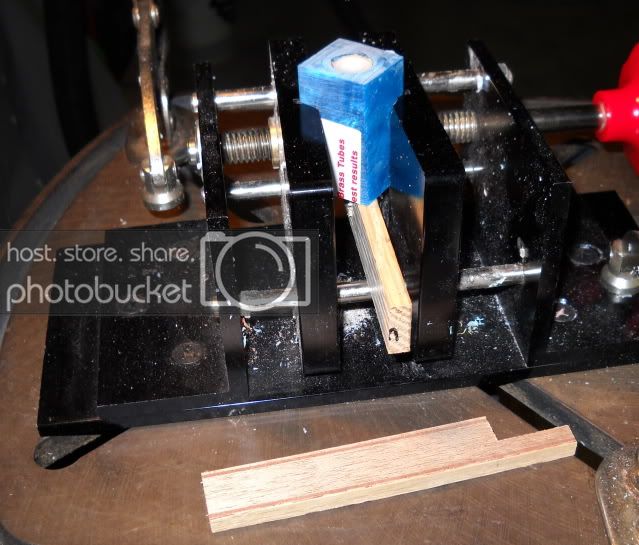

http://www.leevalley.com/wood/page.aspx?c=1&p=54855&cat=1,41659

self centering pen drilling vise.

I hand tighten the wood blank in the vise, start drilling and some harder woods take a bit for the drill to bite and drill down but while its drilling downwards the wood blank seems to slip downwards. I have to open it up and and re-adjust the wood blank upwards then continue to drill. Some wood blanks seem to I dunno push the vise apart alittle maybe. Causing the red handle impossible to turn back without the aid of a pair of pliers.

What do I do? or shall I just get a better vise?