rtjw

Member

I turned one blank with this pen chuck. Turned wonderfully. The only problem was that the blank was to clear. So I turned something that was mostly for trial and error.

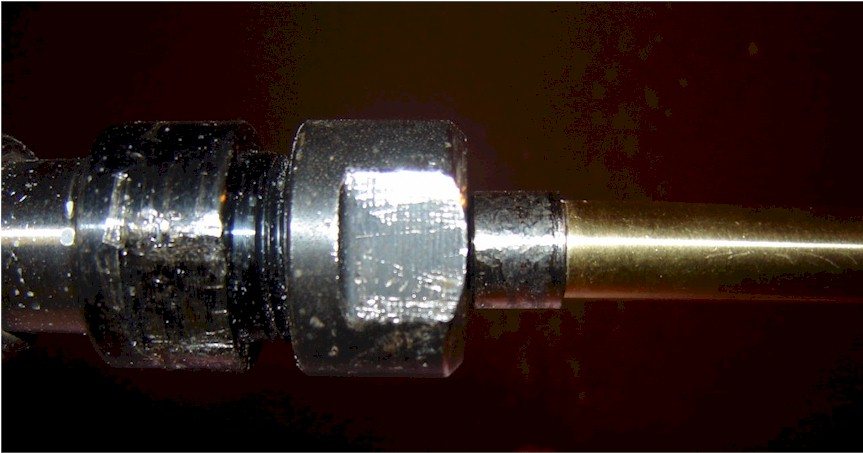

Have been toying with this idea for a while now. I have been thinking, why couldnt you make a pen chuck for a pen mandrel? That way you could make solid body pens without having to change out the whole mandrel. Worked on it for a while and this is what I came up with. Will be trying it out tonight. All you have to do is change out the mandrel shaft. Turns true and doesnt seem to bad. Left about 1/2 inch off the tube end so you can drill the hole far enough. Probably will shorten it a bit.

This piece is for a Jr. gent. It is made to where you can put the bushing on and then the blank.

Have been toying with this idea for a while now. I have been thinking, why couldnt you make a pen chuck for a pen mandrel? That way you could make solid body pens without having to change out the whole mandrel. Worked on it for a while and this is what I came up with. Will be trying it out tonight. All you have to do is change out the mandrel shaft. Turns true and doesnt seem to bad. Left about 1/2 inch off the tube end so you can drill the hole far enough. Probably will shorten it a bit.

This piece is for a Jr. gent. It is made to where you can put the bushing on and then the blank.