its_virgil

Member

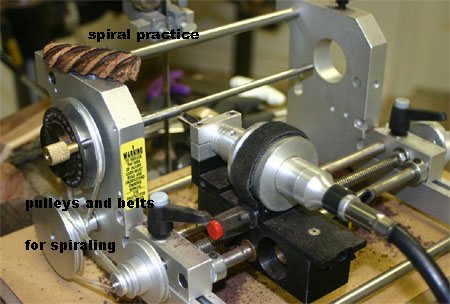

Many of you asked about the baron with the facets and how it was made. Here are some pictures of the ornamental mill I used. It is called 'The MillLathe' and was produced to mill small wooden objects but is now out of production. There are 15 kits that allow tapering, face plate work, center to center turning, template use, and other thins I'm not sure what they are. There is even a mill kit(rotary table) which add the "Y" axis movement. Wish I had that part. Here are some pictures.

Do a good turn daily!

Don

Do a good turn daily!

Don