Old Codger

Member

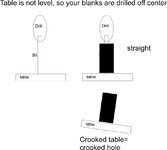

I have to admit I'm a 'Newbie' to Pen Turning but have turned bowls, boxes, bird houses, kitchen tools, etc. for a couple of years and never had an issue like this... I recently started turning pens and purchased all new pen turning tools (i.e.; PSI Pen Blank Drilling Vise, Pen Assembly Press, required brad point drill bits, blank squaring tools, etc.) and find that 3 out of 5 pen blanks that I drill are centered on the top of each blank but off center at the bottom of the blank so much that I feel the blank is a complete loss! I've checked the drill press to be sure it is square and level and that the drill press is running at the correct speed, stop often and clean out the drilled hole and let the wood cool, etc. yet still find that the majority of the blanks I drill are off center at the bottom of the blank... What gives? The wood I've used is Cocabola, Purple Wood, and Walnut blanks from PSI and other suppliers... Any/all assistance/advice will be greatly appreciated! Safe turning to all!