A month or 2 ago an osage orange on my street came down in a storm, I managed to grab a branch or 2 and was wondering if I should let it dry out before cutting it into pen blanks or do so now while it is still green? If I do it now should i make them a little thicker than usual?

Thanks,

-Dutra

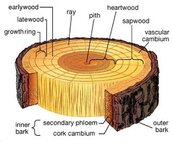

The smaller the wood size. the quicker will dry, naturally...! therefore, the very first thing you should do with those logs is cut them 11" long (makes to blanks in length), then rip it through the centre (pith). If you only want to make straight cut pen blanks, regardless of log diameter, rip the halves in half again and rip everything at about 22 to 25mm square (counting for shrinkage).

If you want to make X (cross) cut blanks, you need ripped boards at 135mm wide, so depending of the log diameter, you have to consider this. If you want to cut Z (diagonal) blanks, those boards need to be 115mm wide, these are all measurements for green wood preparation/processing.

If you think the wood is prone to warp/twist badly while drying, you can deep the blanks in a good wood stabiliser and then stack them up to dry. This is where, the warping/twisting will happen and the best way to minimise this phenomenon, is to have the blanks strapped tight in such way that they can still have some air circulation in between them, accelerating the drying process, considerably compared to stack the blanks on top of each other , touching each other on all sides...!

I call these drying piles, "portable drying stacks" (pic attached) as you can move them easily around the shed/work shop.

Attention: - Do NEVER put these racks (drying blanks) out in the sun...!

:curse: not a good idea...!:frown:

Good luck.

Cheers

George