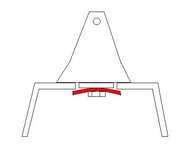

I have a not so old Delta midi lathe (out of warranty) and the tailstock wobbles on the lathe's rails. Is there any way to tighten this up so that alignment between the headstock and tailstock is maintained? It

drove me crazy trying to figure out why my pens were coming out poorly until I discovered this problem. Actually I only discovered it because a bought a full size lathe and decided to try turning a pen on it and it came out beautifully.

Thanks,

Mickey

drove me crazy trying to figure out why my pens were coming out poorly until I discovered this problem. Actually I only discovered it because a bought a full size lathe and decided to try turning a pen on it and it came out beautifully.

Thanks,

Mickey