My Harbor Freight Mini Wood Lathe (8 x 12) has done pretty well, for the price I got it at .... waited for a 25% off coupon and scored it for 104 dollars after tax. It's got a 3/4 x 16 headstock (3/4 inch bolt threads with 16 teeth per inch pitch ... you can buy nuts that fit this at places like Atwoods and Farmer's Supply Co.) which is on the small end of fairly standardized lathe sizes. The other thing you need to know about the spindle and tailstock centers are that they are Morse Taper #1.

This is smaller than MT2, and sometimes it's difficult to find accessories to fit it at a reasonable price... make sure that you get accessories that will fit whichever lathe you end up with in the end.

My lathe came with a 1/3 HP variable speed motor. It hasn't let me down much at all, though sometimes I wish it had a BIT more power to it ... I am still not planning to upgrade from this lathe any time soon, as it fills all my needs at this point. It spins as slow as 250 RPM, which I like for applying CA for my finish, and goes up to about 3600 RPM for my final polishing ... most of my actual lathe work is around 600 RPM for roughing, up to 2000 RPM for balanced turning between centers, 500 - 1000 RPM for sanding. The dial control is VERY convenient and at this point I have no intention of ever buying a lathe without variable speed control, even if I have to retrofit one into an existing lathe. (There are kits out there that can do exactly that, with replacement motors and controllers.)

It is capable of turning a SIX INCH or so bowl blank, and things up to perhaps 13 inches long between centers. I say six inches, not eight, because you'ld need a perfectly round blank centered exactly on the spindle to be able to turn it without hitting the ways, plus you'll want clearance of some sort under the spinning blank so that you can move the banjo around. 90% of my turning is pens, keychains, beads (from leftover cutoffs), and the occasional small box/bowl and plate. One of my recent projects was a 5.5 inch wide key/coin plate for dropping off my keys and emptying my pockets by the door when I come inside ... made from a 1/6 Eastern Redwood Cedar board section. I had to knock the corners off and then mount it on my glue block and turned it. It came out quite nicely ... I left the underside unfinished so that it still has that Cedar smell!

I can do a spindle, as I said, up to 13 inches long ... but I've never put anything on the lathe much over 9 inches. Mostly just to turn it round and true it up ... mark it and cut it for small boxes.

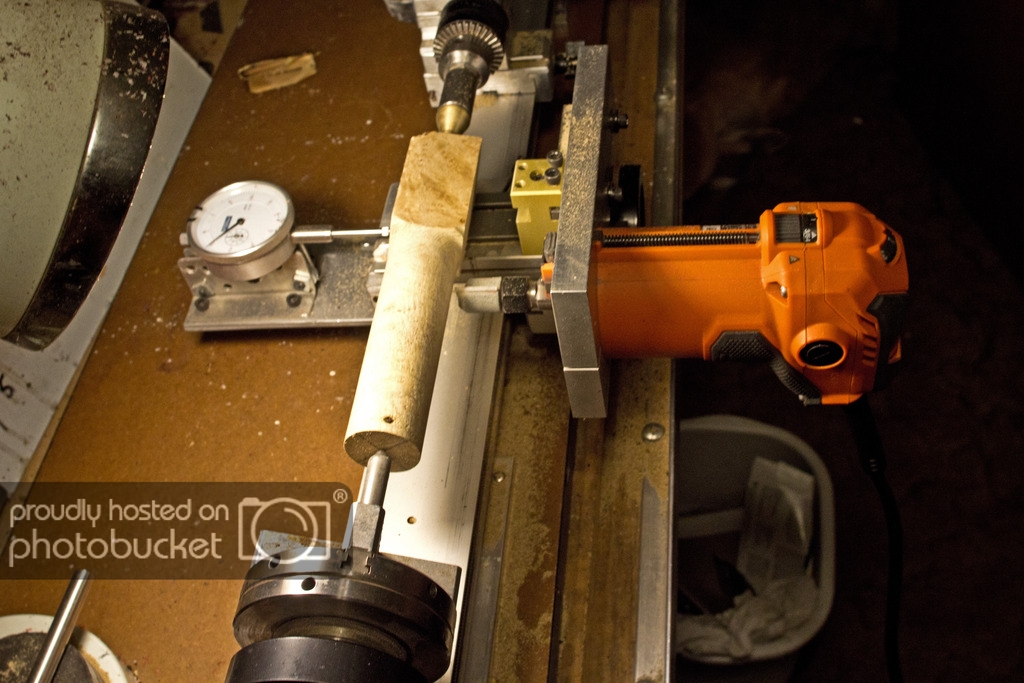

All that having been said, you can see that my lathe is working pretty much well within my capabilities and needs. For a 100 dollar lathe, it's working way better than expected. I do still have issues with the tailstock slipping, so I keep a bar clamp across the ways just behind the tailstock to limit any slippage, and that's worked quite well for me.

If I plan any possible upgrade to this lathe, at this point ... I would probably just spring for the midi upgrade kit from PSI. They have a 1/2 HP motor with speed controller for around 150 dollars which looks decent. Another possible plan would be the same upgrade kit, but applied to the larger benchtop lathe from Harbor Freight... I'ld have to get 1x8 and MT2 accessories for it, but being able to turn larger things doesn't necessarily mean that I'ld do a better job at making small items than on my smaller lathe already.

I know this is a pretty long and detailed post, but I hope that it gives you some direction on what to really look for in a lathe "upgrade" for the future.

Last, but not least ... when I'm ready to take the plunge ... I plan to actually MAKE my own lathe, similar to one made by Matthias Wendel, but with a variable speed control system.