mmayo

Member

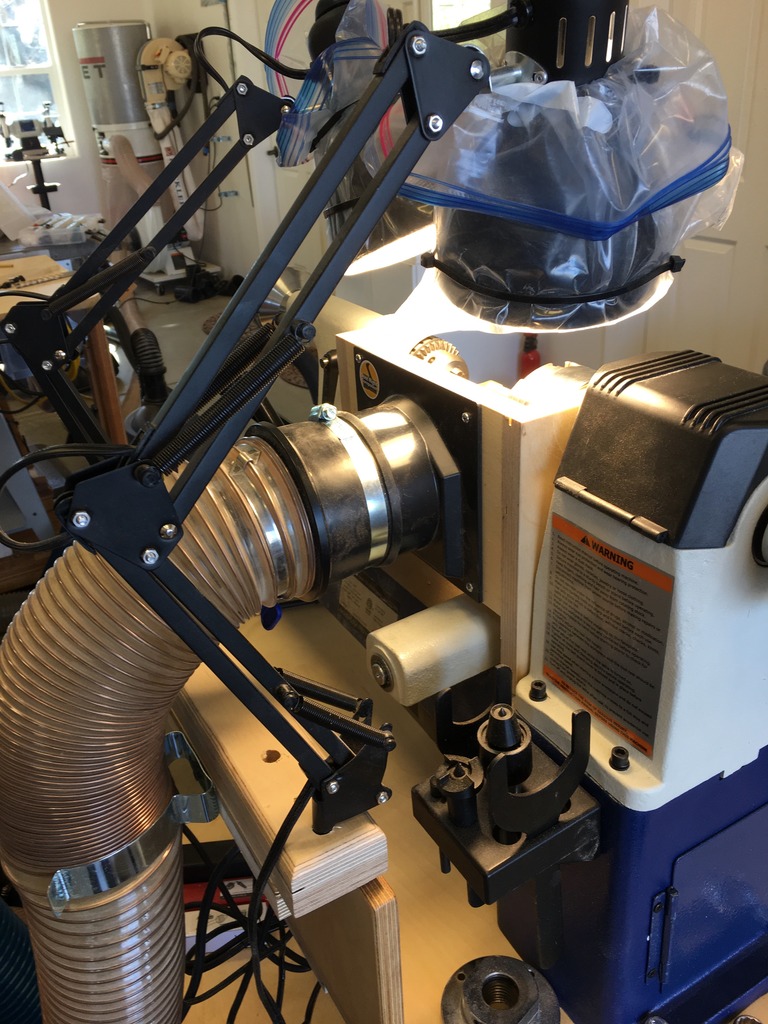

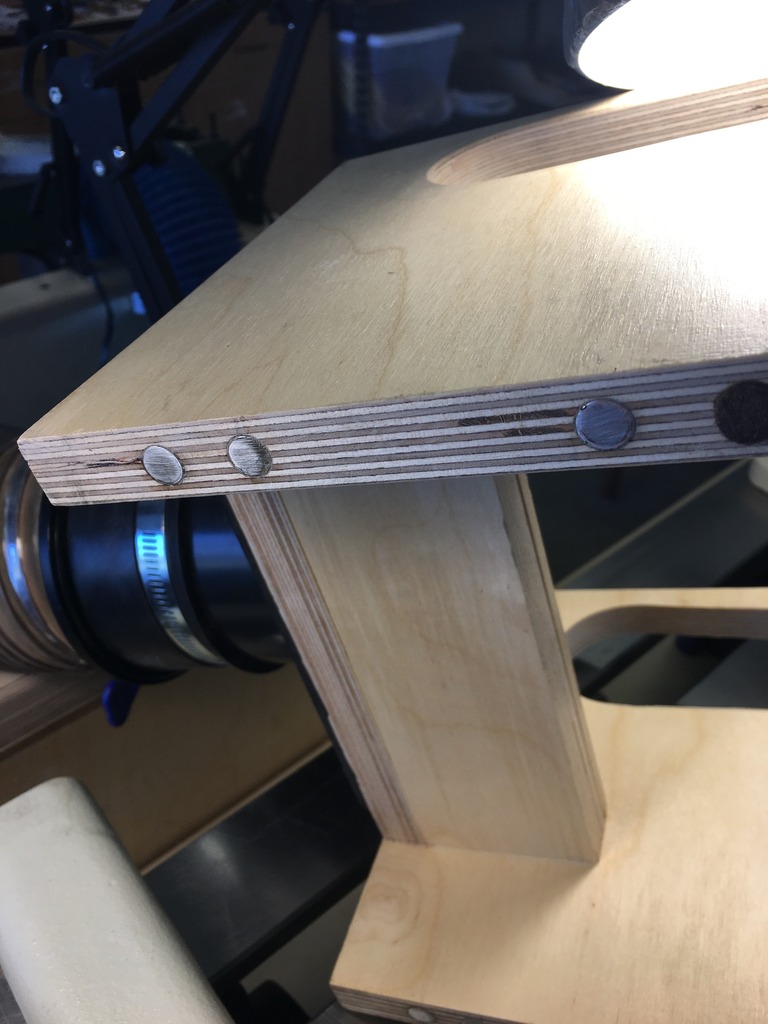

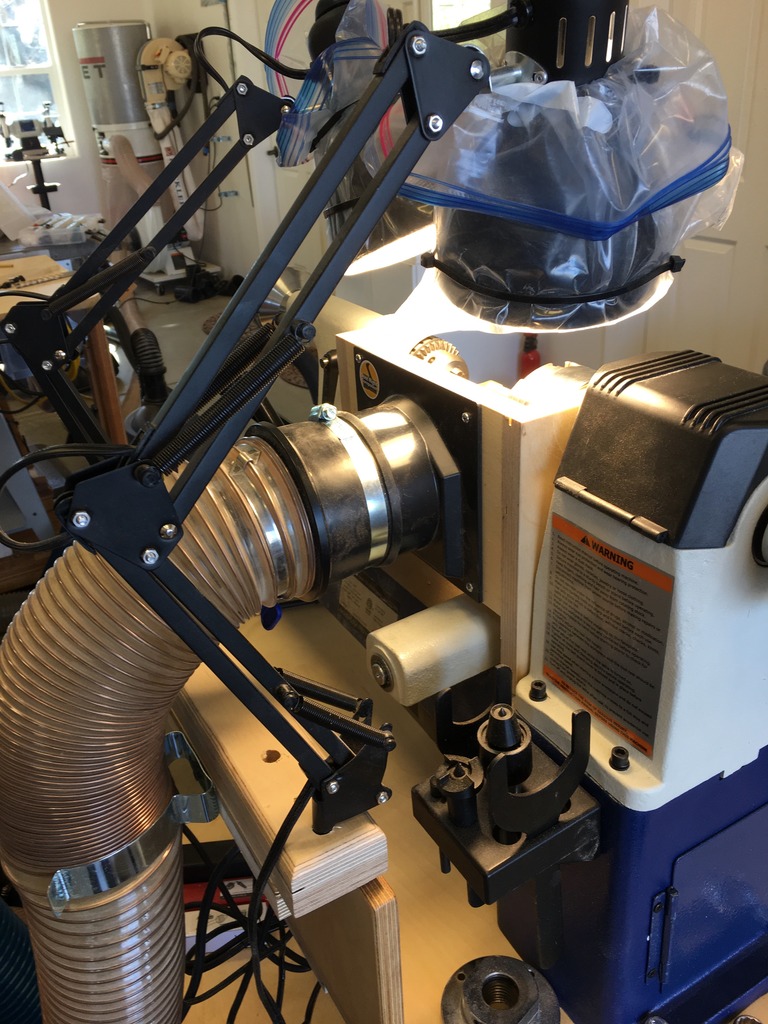

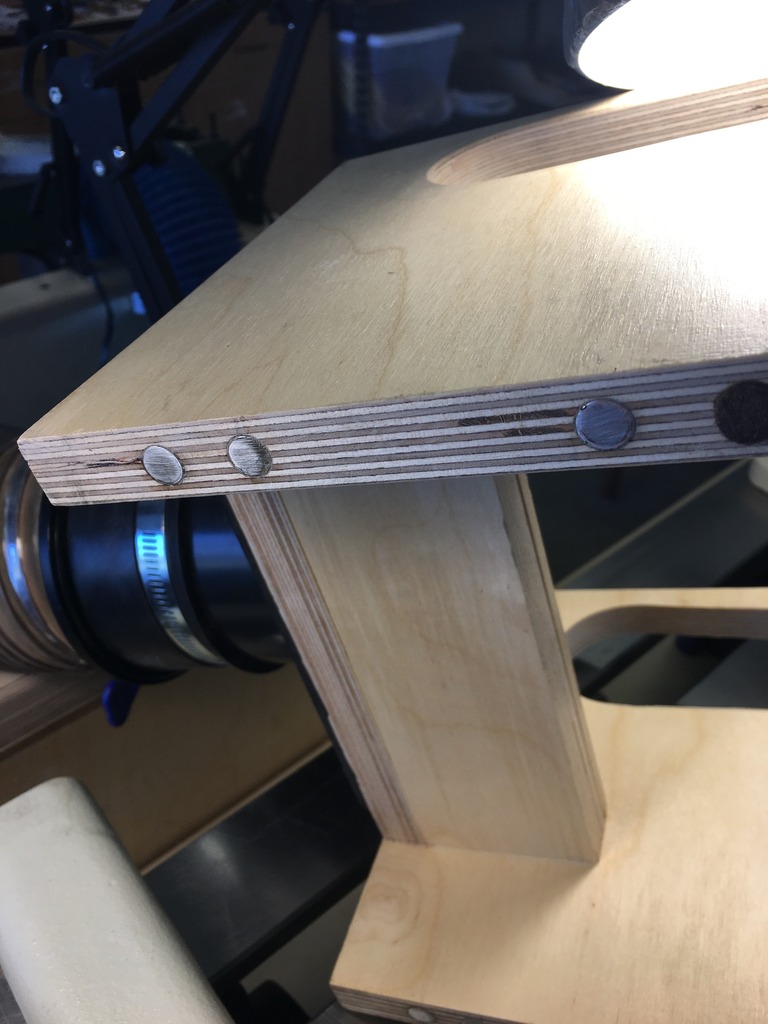

I've never been one to leave well enough alone. So I reinvented my dust collection system and it's better. The new system is structured around shop made wooden dust collection structures that I've seen here on this site. I made one for each of my two lanes and they use 4" hoses to carry the dust and chips to my Jet. A blast gate determines which tool connects to the vacuum. The plywood collector is held in place to the lathe using six 3/8" neodymium magnets.

After drilling twenty blanks today and turning quite a few recently, this gets the most chips and dust so far. Little cleanup means more fun and less work.

The table saw and router have similar blast gates connected to the Jet. I just need to always open the correct gate.

After drilling twenty blanks today and turning quite a few recently, this gets the most chips and dust so far. Little cleanup means more fun and less work.

The table saw and router have similar blast gates connected to the Jet. I just need to always open the correct gate.

Last edited: