No matter which way you cut your blank when making a cross ( Celtic Knot ) don't cut all the way through. Use a slightly bigger blank and just cut about 3/4 the way through. This means the blank will always stay perfectly aligned. If you use a tablesaw then lower the blade. If you use a chopsaw, then raise the blade using the depth stop. If you use a bandsaw you could do what I did. Just put a clamp on the end of the mitre slide to act as a stop. Hope this helps

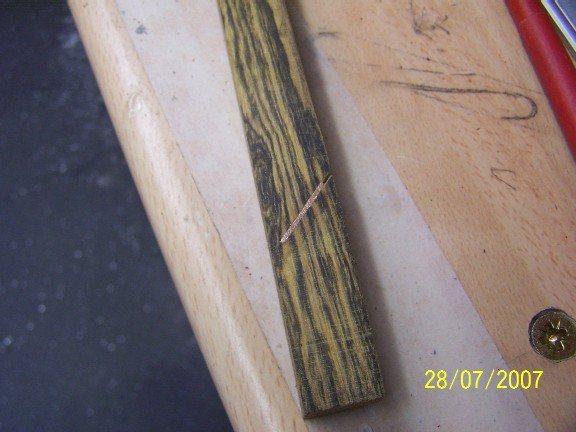

First cut, see how it doesn't cut through the blank completely

Second cut...

Fourth cut...

Drill and add tube...

Turn as normal...

Heres how I cut for thin stuff....

The clamp on the end of the mitre acts as the depth stop ( and prevents me cutting all the way through my zero clearance fence )

)

Hope this helps

First cut, see how it doesn't cut through the blank completely

Second cut...

Fourth cut...

Drill and add tube...

Turn as normal...

Heres how I cut for thin stuff....

The clamp on the end of the mitre acts as the depth stop ( and prevents me cutting all the way through my zero clearance fence

Hope this helps