Hello all, well it is time to try my hand at closed end cigars and I was wondering which you guys thought would work best for holding the closed end pin chucks from AZS, a jacobs chuck or a collet chuck like Beall or the PSI version? Currently I do not own any kind of a chuck.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jacobs or collet chuck???

- Thread starter refueler1

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

rherrell

Member

If I didn't own ANY kind of a chuck I think I'd go with a Jacobs for my first. They're relatively inexpensive and they'll do a fine job holding closed end mandrels. Do you have a drill press? If you do, check out the chuck in it, you might get lucky. Having said all that, I would be LOST without my Beall. IMO it's the handiest chuck there is for turning pens.

Jack,

I bought the Beall collet first from CSUSA and I bought a full set of ER32 collets for it from 800WATT on Ebay. If I had to do it again I would have bought the Jacobs chuck first.

I have the DVD by Ed Davidson (yoyospin) "Closed-End Pens Design & Turning Techniques and he uses a Jacobs chuck to hold the mandrels.

I can see advantages really to having both the Beall collet and a Jacobs chuck too. So if I had to do it again I might have been tempted to start with a Jacobs chuck and then add a Beall collet latter.

The Beall collet does let me run the "A" mandrel as deep into as I like since the headstock is hollow. Which I sometimes do if I am turning something like a perfume vial pendant.

I have noticed that out of round (oval or off center) turning is a problem of the past since I started using the Beall collet.

I will be buying a Jacobs chuck soon because I want to turn pepper mills and some other projects that will need deep material removal by drilling.

I bought the Beall collet first from CSUSA and I bought a full set of ER32 collets for it from 800WATT on Ebay. If I had to do it again I would have bought the Jacobs chuck first.

I have the DVD by Ed Davidson (yoyospin) "Closed-End Pens Design & Turning Techniques and he uses a Jacobs chuck to hold the mandrels.

I can see advantages really to having both the Beall collet and a Jacobs chuck too. So if I had to do it again I might have been tempted to start with a Jacobs chuck and then add a Beall collet latter.

The Beall collet does let me run the "A" mandrel as deep into as I like since the headstock is hollow. Which I sometimes do if I am turning something like a perfume vial pendant.

I have noticed that out of round (oval or off center) turning is a problem of the past since I started using the Beall collet.

I will be buying a Jacobs chuck soon because I want to turn pepper mills and some other projects that will need deep material removal by drilling.

Last edited:

Larry Gottlieb

Member

I recently bought a Beal collet chuck and found that the runout of my mandrels is much greater than when using a drill driver with the same mandrels.

Larry

Larry

its_virgil

Member

A jacob's chuck will work but be sire to get one that has the threaded hole in the end of the taper arbor so you can use a draw bar to hold the jacob's chuck in the headstock.

I have two and only use them for drilling. I have the beall collet chuck with the full set of collets and use them for holding pen parts as well as tools.

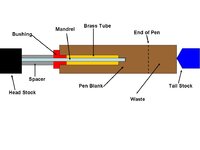

If you don't currently have special mandrels for making closed end pens then be ware that you don't need them. There are several ways to hold the pen blank for making a closed end pen. One used the standard mandrel with no special tooling needed. Here is a picture of the set up and you may want to read a couple of articles I've written for a woodturning magazine on making closed end pens. They can be found at http://www.RedRiverPens.com/articles.

Do a good turn daily!

Don

I have two and only use them for drilling. I have the beall collet chuck with the full set of collets and use them for holding pen parts as well as tools.

If you don't currently have special mandrels for making closed end pens then be ware that you don't need them. There are several ways to hold the pen blank for making a closed end pen. One used the standard mandrel with no special tooling needed. Here is a picture of the set up and you may want to read a couple of articles I've written for a woodturning magazine on making closed end pens. They can be found at http://www.RedRiverPens.com/articles.

Do a good turn daily!

Don

Hello all, well it is time to try my hand at closed end cigars and I was wondering which you guys thought would work best for holding the closed end pin chucks from AZS, a jacobs chuck or a collet chuck like Beall or the PSI version? Currently I do not own any kind of a chuck.

Attachments

its_virgil

Member

Hey Larry,

You should contact J R Beall at Beall Tool Company and get a replacement...or complain to the vendor where you bought it. There should be minimal runout. I know others who complained and had the problem fixed.

Do a good turn daily!

Don

You should contact J R Beall at Beall Tool Company and get a replacement...or complain to the vendor where you bought it. There should be minimal runout. I know others who complained and had the problem fixed.

Do a good turn daily!

Don

I recently bought a Beal collet chuck and found that the runout of my mandrels is much greater than when using a drill driver with the same mandrels.

Larry

Chuck Key

Member

IMO it's the handiest chuck there is for turning pens.

I use Beall, I use Jacobs and I use several others but the one I seem to go to most is a four jaw independent chuck.

Hello, I did read your article and found your none chuck method to be a good idea. Mr. Wards video shows him usung a jacobs chuck and he did not glue the brass sleeve in the blank before turning so he had to use masking tape to help hold the tails stock against the blank so that the blank would not spin on the brass tube. I might try this method first but will probably buy some kind of chuck since I will eventually need one. Just dont know what I will need first???

PaulDoug

Member

I bought a beall chuck last week. Worth each and every penny I soent on it!

I bought a beall chuck last week. Worth each and every penny I soent on it!

Do you think the beall chuck will hold a pen mandrel better than a jacobs? I have my eye on the PSI version but folks have suggested I get a jacobs chuck first. Maybe I'll just buy both.

PaulDoug

Member

I like the fact it screws on the spindle rather than the Morse taper, seems more accurate to me. I don't know about the PSI collet chuck, never used or seen one. I know I had one from woodcraft that I was not at all happy with. Besides a definite wobble, I could not buy other collets for it. You will use both a collet chuck and a Jacobs chuck a lot, least I do. If you can afford it get both, you won't be sorry. By the way, I find using the mandrel in the collet chuck has much less run out than mounting the mandrill in the Morse taper.

Yes, Larry, I would contact Beall about that chuck.

Yes, Larry, I would contact Beall about that chuck.

ldb2000

Member

The Chuck no one has mentioned yet is a scroll chuck , I have both the PSI collet chuck and a Jacobs chuck but almost never use either (in the headstock) , I use the Barracuda2 chuck from PSI for almost everything from holding my 7mm mandrel to holding blanks for drilling .

It is the most versatile accessory I have purchased for my lathe (Jet 1014 vs) and is useful for everything from pens to small bowls .

A word of warning about the Jacobs chuck in the head stock , if you are turning anything without the tail stock holding it in you MUST use a draw bolt to keep the chuck from becoming a projectile , the Morse taper WILL NOT lock the chuck in place and it only takes a second for it to loosen up and go flying across the shop

It is the most versatile accessory I have purchased for my lathe (Jet 1014 vs) and is useful for everything from pens to small bowls .

A word of warning about the Jacobs chuck in the head stock , if you are turning anything without the tail stock holding it in you MUST use a draw bolt to keep the chuck from becoming a projectile , the Morse taper WILL NOT lock the chuck in place and it only takes a second for it to loosen up and go flying across the shop

Last edited:

The Chuck no one has mentioned yet is a scroll chuck , I have both the PSI collet chuck and a Jacobs chuck but almost never use either (in the headstock) , I use the Barracuda2 chuck from PSI for almost everything from holding my 7mm mandrel to holding blanks for drilling .

It is the most versatile accessory I have purchased for my lathe (Jet 1014 vs) and is useful for everything from pens to small bowls .

a word of warning about the Jacobs chuck in the head stock , if you are turning anything without the tail stock holding it in you MUST use a draw bolt to keep the chuck from becoming a projectile , the Morse taper WILL NOT lock the chuck in place and it only takes a second for it to loosen up and go flying across the shop

I was going to order the BC2 but after asking here everyone has suggested I start out with a jacobs chuck. Will the BC2 hold the closed end pen mandrels and without the jaws getting in the way? My option is to buy the BC2 or buy the collet and jacobs chuck. Which jaws do you use to hold a small mandrel? I have never used a scroll chuck before.

d1carter

Member

refeuler1:

I use the PSI collet chuck to make closed end pens, bottle stoppers, shaving brush handles, duck calls and other things. I have enjoyed the freedom this chuck has given me. I make shop made mandrels for most of the things I make. I still make regular pens on the old morse taper pen mandrel. I only use the Jacobs chuck in the tail stock for drilling. Give any of them a try, see what you like and what is easier for you.

I use the PSI collet chuck to make closed end pens, bottle stoppers, shaving brush handles, duck calls and other things. I have enjoyed the freedom this chuck has given me. I make shop made mandrels for most of the things I make. I still make regular pens on the old morse taper pen mandrel. I only use the Jacobs chuck in the tail stock for drilling. Give any of them a try, see what you like and what is easier for you.

ldb2000

Member

Jack if all you are going to make is closed end pens and other small turnings then either the PSI (or Beall) collet chuck or the Jacobs chuck will serve you very well .

If you think you will ever want to get into kitless pens or small bowls and boxes then the BC2 would be the better buy .

I make kitless pens and small bowls and lidded boxes and pendent watches and the collet chuck requires that I make jam chucks and pin chucks and waste alot of time making these jigs and mandrels .

As for using a Morse taper mandrel for pens , be my guest but if you do a search here for out of round pens you will find the most of the time it's the mt mandrels that are to blame , you would be far better off turning your pens between centers using the regular bushings then using an MT mandrel (JohnnyCNC's bushings are best but until he gets his life back together the regular bushings between centers work far better then any mandrel).

The jaws really don't get in the way for the closed end mandrels and most other turning but you do have to use more care around the chuck end .

I use the step jaws for most of the smaller things I turn and for precision drilling on the lathe .

If you think you will ever want to get into kitless pens or small bowls and boxes then the BC2 would be the better buy .

I make kitless pens and small bowls and lidded boxes and pendent watches and the collet chuck requires that I make jam chucks and pin chucks and waste alot of time making these jigs and mandrels .

As for using a Morse taper mandrel for pens , be my guest but if you do a search here for out of round pens you will find the most of the time it's the mt mandrels that are to blame , you would be far better off turning your pens between centers using the regular bushings then using an MT mandrel (JohnnyCNC's bushings are best but until he gets his life back together the regular bushings between centers work far better then any mandrel).

The jaws really don't get in the way for the closed end mandrels and most other turning but you do have to use more care around the chuck end .

I use the step jaws for most of the smaller things I turn and for precision drilling on the lathe .

Butch, thanks for the info. If I were to get a BC2 could I still use the closed end mandrels or will it be easier with the collet chuck. Yes I would like to expand my lathe experience beyond pens. Making pens is the first thing I started after I purchased my lathe. BTW, what is a kitless pen?

alamocdc

Member

Jack, this is JMO, but I'd use a 4 jaw scroll chuck or a collet chuck (I have 2 Beall's) before I'd use a drill chuck for holding anything in the headstock. And possible runout is the least of the reasons. The primary rationale behind my choice is that both the collet and scroll chucks are hollow in the center. This means that the madrel being held can be inserted to virtually any desired length. You cannot do this with a drill chuck (at least non of them I've seen) since the MT - drill chuck adapter is hollow. Even if it were, the hole would have to be rather small to leave enough strength. So for me this isn't an option. Again, JMO.

rjwolfe3

Member

I just bought a drill chuck from AS to use with his closed end mandrels, should I send it back and buy a collet chuck?????

Jack, this is JMO, but I'd use a 4 jaw scroll chuck or a collet chuck (I have 2 Beall's) before I'd use a drill chuck for holding anything in the headstock. And possible runout is the least of the reasons. The primary rationale behind my choice is that both the collet and scroll chucks are hollow in the center. This means that the madrel being held can be inserted to virtually any desired length. You cannot do this with a drill chuck (at least non of them I've seen) since the MT - drill chuck adapter is hollow. Even if it were, the hole would have to be rather small to leave enough strength. So for me this isn't an option. Again, JMO.

Thanks alamocdc for your response. I initially wanted to get the BC2 but just wondering if it will hold a mandrel as good as the collet chuck would and then there is those sharp points on the rotating jaws to watch out for. I cant order anything until this Friday anyway so I have a few more days to make up my mind. I can offored to get either the BC2 or I can get both the collet chuck and a jacobs chuck but not all three.

rherrell

Member

No contest, get the collet and the Jacobs chucks. I know you're planning on buying from PSI, just keep in mind that the collets that come in their set are 1/8" apart. ER32 collets, which these are, don't have a gripping range that wide. At the very least you'll need a 5/16" for your "B" mandrel, if you use mandrels. I'm pretty sure the closed end mandrels you plan on getting from AS all take 1/2" so you're covered there. Once you get a collet chuck you'll find yourself using it for everything so a full set is worth it.Thanks alamocdc for your response. I initially wanted to get the BC2 but just wondering if it will hold a mandrel as good as the collet chuck would and then there is those sharp points on the rotating jaws to watch out for. I cant order anything until this Friday anyway so I have a few more days to make up my mind. I can offored to get either the BC2 or I can get both the collet chuck and a jacobs chuck but not all three.

As far as the Jacobs chuck goes, 1/2" is the smallest I would get. I happen to like the keyless ones but alot of people don't because they say they slip, I haven't had that problem. If you don't try and force them into the material and if you clear the bit often they work fine. For me, using a key all the time is a PITA, especially for drilling casings and bullets where you change bits alot.

GOOD LUCK!

alamocdc

Member

I just bought a drill chuck from AS to use with his closed end mandrels, should I send it back and buy a collet chuck?????

Rob, if it's 1/2", I'd keep it. It will come in very handy for drilling on the lathe, etc. I use one quite often for drilling things like casing pens. I just don't use it on the headstock since I have a Beall and a scroll chuck. These two meet all of my gripping needs at that end.

I have an opinion on chucks that comes from a lifetime of using them, and measuring their run-out with a dial indicator. For what it's worth, here it is - -

1 Nowhere is it more true that you get what you pay for than with chucks.

2. The average run-out of a scroll chuck made for woodturning is in the range of 0.003" to 0.005", and it isn't difficult to find one that is closer to 0.010". You are extremely lucky if you have one that is better than that. There are scroll type chucks made with accuracy of 0.001", but they are for precision machine work and cost several hundred dollars.

3. The average Jacobs chuck will be within the same 0.003" to 0.005" when new, and it will deteriorate with age because of wear of the many moving parts inside of it. The run-out problem is compounded by the Morse Taper and the fact that it isn't at all difficult to find a lathe, in the price range most paid for it, whose internal MT is not in perfect alignment with the bore. A small angular difference can add up to several 1/1000" run-out at the end of the chuck.

The consistently most accurate Jacobs chuck I have found is the "Golden Goose" brand that is sold by Craft Supplies and Woodcraft stores. You can buy cheaper, but this is the best accuracy (0.003" or less) you will find for about $40.00. There are more accurate Jacobs chucks available, but they will cost several hundred dollars.

4. The Bealle and similar collet chucks will have a run-out on the order of 0.001". It is unusual to find a chuck with more than that, and if you did, you should be contacting the manufacturer or the point of purchase for a replacement.

The chuck that threads onto the spindle is more accurate than the one that uses the MT in the spindle because the threads were cut at the same time as the spindle was turned and they are more accurate than the MT (see 2 above) which are usually machined as a separate operation.

There are MT chucks available, but they are less accurate (see above) and work best when the srock being held is the nominal size of the collet because they are split from only one end. The ER 25 and ER32 collets are split from both ends and have equal accuracy and gripping over a range of about 1/64" larger to 1/32" smaller than the nominal size of the collet.

5. The best and the worst of all ways to hold a mandrel is the tapered adapter with the mandrel screwed into the end of a MT that fits in the lathe. First, there is the problem with the MT in the lathe, as noted above. Then there is the possibility that the drilled and tapped hole in the adapter in not centered or is not parallel with the lathe, and the possibility that the same is true for the threaded end on the mandrel. In the best of conditions, all tollerances are minimal or they cancel each other, and we have an accurate mandrel. The worst case is when the tolerance all add in the same direction, and we have the least accurate mandrel. Unfortunately, only 20% are the best. 20% are the worst, and the rest are somewhere in between.

1 Nowhere is it more true that you get what you pay for than with chucks.

2. The average run-out of a scroll chuck made for woodturning is in the range of 0.003" to 0.005", and it isn't difficult to find one that is closer to 0.010". You are extremely lucky if you have one that is better than that. There are scroll type chucks made with accuracy of 0.001", but they are for precision machine work and cost several hundred dollars.

3. The average Jacobs chuck will be within the same 0.003" to 0.005" when new, and it will deteriorate with age because of wear of the many moving parts inside of it. The run-out problem is compounded by the Morse Taper and the fact that it isn't at all difficult to find a lathe, in the price range most paid for it, whose internal MT is not in perfect alignment with the bore. A small angular difference can add up to several 1/1000" run-out at the end of the chuck.

The consistently most accurate Jacobs chuck I have found is the "Golden Goose" brand that is sold by Craft Supplies and Woodcraft stores. You can buy cheaper, but this is the best accuracy (0.003" or less) you will find for about $40.00. There are more accurate Jacobs chucks available, but they will cost several hundred dollars.

4. The Bealle and similar collet chucks will have a run-out on the order of 0.001". It is unusual to find a chuck with more than that, and if you did, you should be contacting the manufacturer or the point of purchase for a replacement.

The chuck that threads onto the spindle is more accurate than the one that uses the MT in the spindle because the threads were cut at the same time as the spindle was turned and they are more accurate than the MT (see 2 above) which are usually machined as a separate operation.

There are MT chucks available, but they are less accurate (see above) and work best when the srock being held is the nominal size of the collet because they are split from only one end. The ER 25 and ER32 collets are split from both ends and have equal accuracy and gripping over a range of about 1/64" larger to 1/32" smaller than the nominal size of the collet.

5. The best and the worst of all ways to hold a mandrel is the tapered adapter with the mandrel screwed into the end of a MT that fits in the lathe. First, there is the problem with the MT in the lathe, as noted above. Then there is the possibility that the drilled and tapped hole in the adapter in not centered or is not parallel with the lathe, and the possibility that the same is true for the threaded end on the mandrel. In the best of conditions, all tollerances are minimal or they cancel each other, and we have an accurate mandrel. The worst case is when the tolerance all add in the same direction, and we have the least accurate mandrel. Unfortunately, only 20% are the best. 20% are the worst, and the rest are somewhere in between.

Last edited:

its_virgil

Member

Not my video....I've not made one. I tried but the camera kept breaking.

Do a good turn daily!

Don

Do a good turn daily!

Don

Mr. Wards video shows him usung a jacobs chuck and he did not glue the brass sleeve in the blank before turning so he had to use masking tape to help hold the tails stock against the blank so that the blank would not spin on the brass tube.

No contest, get the collet and the Jacobs chucks. I know you're planning on buying from PSI, just keep in mind that the collets that come in their set are 1/8" apart. ER32 collets, which these are, don't have a gripping range that wide. At the very least you'll need a 5/16" for your "B" mandrel, if you use mandrels. I'm pretty sure the closed end mandrels you plan on getting from AS all take 1/2" so you're covered there. Once you get a collet chuck you'll find yourself using it for everything so a full set is worth it.

As far as the Jacobs chuck goes, 1/2" is the smallest I would get. I happen to like the keyless ones but alot of people don't because they say they slip, I haven't had that problem. If you don't try and force them into the material and if you clear the bit often they work fine. For me, using a key all the time is a PITA, especially for drilling casings and bullets where you change bits alot.

GOOD LUCK!

Sooo the PSI chuck should work fine?? What else is the collet chuck good for when it comes to making pens?

Not my video....I've not made one. I tried but the camera kept breaking.

Do a good turn daily!

Don

Sorry, it was Ed Davidsons video on the cigar closed end pen from the IAP articles.

Simple answer - I use all 3. That's because I drill blanks on the lathe.

I use a collet chuck to hold mandrels. All of my mandrel problems disappeared when I started using a collet chuck.

The only thing I use the Jacobs chuck for is holding a drill in the tail stock for drilling, while the scroll chuck is holding the square blank in the headstock. I don't need either one if I drill the blanks on the drill press.

I use a collet chuck to hold mandrels. All of my mandrel problems disappeared when I started using a collet chuck.

The only thing I use the Jacobs chuck for is holding a drill in the tail stock for drilling, while the scroll chuck is holding the square blank in the headstock. I don't need either one if I drill the blanks on the drill press.

ldb2000

Member

Ok so as you can see there is no simple answer to your question , some of us swear by the collet chuck and as I said if all you will be turning is closed end pens and bottle stoppers and for using to hold your mandrels then the collet chuck is for you .

If you plan on doing other kinds of small turnings or drilling on the lathe or more advanced types of pen turning then a scroll chuck will serve you better .

As for the Jacobs chuck as Russ said just use it in the tailstock for drilling on the lathe .

I purchased the collet chuck because it was cheaper then the scroll chuck and I never thought I would be expanding the things I make (I was wrong and had to buy the BC2 anyway so no money was saved) , if I were to start again I would not even buy the collet chuck (the money could have gone to a better skew or alot of blanks and kits) .

JUST MY OPINION the scroll chuck has been more then accurate enough to do any of the tasks that I have asked it to perform and the versatility that it offers makes it my most used work holder

If you plan on doing other kinds of small turnings or drilling on the lathe or more advanced types of pen turning then a scroll chuck will serve you better .

As for the Jacobs chuck as Russ said just use it in the tailstock for drilling on the lathe .

I purchased the collet chuck because it was cheaper then the scroll chuck and I never thought I would be expanding the things I make (I was wrong and had to buy the BC2 anyway so no money was saved) , if I were to start again I would not even buy the collet chuck (the money could have gone to a better skew or alot of blanks and kits) .

JUST MY OPINION the scroll chuck has been more then accurate enough to do any of the tasks that I have asked it to perform and the versatility that it offers makes it my most used work holder

rherrell

Member

Sooo the PSI chuck should work fine?? What else is the collet chuck good for when it comes to making pens?

It looks like a Beall knock off so in theory it should work like one, but buyer beware. I've never used one so I can't say, however, it's been my experience that you get what you pay for. The Beall has proven itself to be a fine chuck, in fact the runout on mine is .0005".

There is one thing that jumped out at me and that's the PSI chuck only comes equipped for a 1"X8tpi headstock spindle so check yours before you order one.

What else is it good for? How wild is your imagination? If you plan on doing casing pens it's invaluable.

Ok so as you can see there is no simple answer to your question , some of us swear by the collet chuck and as I said if all you will be turning is closed end pens and bottle stoppers and for using to hold your mandrels then the collet chuck is for you .

If you plan on doing other kinds of small turnings or drilling on the lathe or more advanced types of pen turning then a scroll chuck will serve you better .

As for the Jacobs chuck as Russ said just use it in the tailstock for drilling on the lathe .

I purchased the collet chuck because it was cheaper then the scroll chuck and I never thought I would be expanding the things I make (I was wrong and had to buy the BC2 anyway so no money was saved) , if I were to start again I would not even buy the collet chuck (the money could have gone to a better skew or alot of blanks and kits) .

JUST MY OPINION the scroll chuck has been more then accurate enough to do any of the tasks that I have asked it to perform and the versatility that it offers makes it my most used work holder

Yeah, there is no good direct answer, thought as much when I posted but wanted to get others experience with the different chucks. Since I will eventually need all three I guess I will get the collet first then the other two next month.

I appreciate everyones help and experience on this subject. I look forward to reading more posts at IAP.

It looks like a Beall knock off so in theory it should work like one, but buyer beware. I've never used one so I can't say, however, it's been my experience that you get what you pay for. The Beall has proven itself to be a fine chuck, in fact the runout on mine is .0005".

There is one thing that jumped out at me and that's the PSI chuck only comes equipped for a 1"X8tpi headstock spindle so check yours before you order one.

What else is it good for? How wild is your imagination? If you plan on doing casing pens it's invaluable.

Well, the PSI has received good reviews and no one has complained of run-out so I guess it wont be an issue, I HOPE. I have the Jet 1014 so the PSI will fit perfect. So, what am I going to get, well, I have decided to get a collet chuck first then the jacobs and scroll chcuks later. The collet chuck I would use immediately, the other two I haven't a need for them yet so they can wait a little longer. Thanks for your replies.

redfishsc

Member

Some folks have mentioned Beall collets that do not run true--- be sure that the problem isn't your lathe's threads before you send it back or you'll have the same issue all over again.

A fat 1" washer put onto your headstock prior to attaching the collet chuck may well solve your problem. I have a Delta and the threads on it bottom out in the Beall and the Barracuda chuck, making them run out of round. With the washer, they run dead-nuts accurate (well, for our purposes).

I have the CSA "Golden Goose" (I did not know that's what I was buying when I ordered it but I love it), a Barracuda chuck, and a Beall collet chuck.

BE SURE YOU ARE BUYING AT LEAST A 1/2" DRILL CHUCK. There are a few 3/8" chucks out there that will make you very sad if you buy them.

When you buy the collet chuck, buy it with ESPECIALLY the 1/4" collet for regular mandrels, 5/32" collets for "B" mandrels from Berea, 3/8" and 1/2" collets. These are not cheap, but worth it.

ALSO NOTE: Not all of Arizonasilhouette's closed-end mandrels will use the same collet. The Baron mandrel uses a 1/2" collet, the slimline closed-end uses something totally different (I can't remember off hand) and I wind up using the drill chuck.

A fat 1" washer put onto your headstock prior to attaching the collet chuck may well solve your problem. I have a Delta and the threads on it bottom out in the Beall and the Barracuda chuck, making them run out of round. With the washer, they run dead-nuts accurate (well, for our purposes).

I have the CSA "Golden Goose" (I did not know that's what I was buying when I ordered it but I love it), a Barracuda chuck, and a Beall collet chuck.

BE SURE YOU ARE BUYING AT LEAST A 1/2" DRILL CHUCK. There are a few 3/8" chucks out there that will make you very sad if you buy them.

When you buy the collet chuck, buy it with ESPECIALLY the 1/4" collet for regular mandrels, 5/32" collets for "B" mandrels from Berea, 3/8" and 1/2" collets. These are not cheap, but worth it.

ALSO NOTE: Not all of Arizonasilhouette's closed-end mandrels will use the same collet. The Baron mandrel uses a 1/2" collet, the slimline closed-end uses something totally different (I can't remember off hand) and I wind up using the drill chuck.

Some folks have mentioned Beall collets that do not run true--- be sure that the problem isn't your lathe's threads before you send it back or you'll have the same issue all over again.

A fat 1" washer put onto your headstock prior to attaching the collet chuck may well solve your problem. I have a Delta and the threads on it bottom out in the Beall and the Barracuda chuck, making them run out of round. With the washer, they run dead-nuts accurate (well, for our purposes).

I have the CSA "Golden Goose" (I did not know that's what I was buying when I ordered it but I love it), a Barracuda chuck, and a Beall collet chuck.

BE SURE YOU ARE BUYING AT LEAST A 1/2" DRILL CHUCK. There are a few 3/8" chucks out there that will make you very sad if you buy them.

When you buy the collet chuck, buy it with ESPECIALLY the 1/4" collet for regular mandrels, 5/32" collets for "B" mandrels from Berea, 3/8" and 1/2" collets. These are not cheap, but worth it.

ALSO NOTE: Not all of Arizonasilhouette's closed-end mandrels will use the same collet. The Baron mandrel uses a 1/2" collet, the slimline closed-end uses something totally different (I can't remember off hand) and I wind up using the drill chuck.

Well, I am going to purchase the PSI collet chuck set, $90. If it is off then I will send it back, but so far no one has had any issues with theirs being off. It does not come with a 5/32 collet so I would have to get one from Enco. As for the chuck, I was looking at getting a 3/4" keyed chuck (keyed so I can ensure a tight fit on the bit). After I have turned more pens then I will probably order a scroll chuck to learn how to make lidded jars and such. As far as closed end pens, the only ones I really want to make are cigar and variations of the slimline. I'm not to interested in fancy rollerballs and FPs.