mikeschn

Member

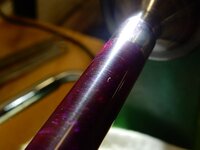

Well I turned my first Alumilite resin blank...

The description is:

Alumilite resin that is known for its beauty, resilience and durability. Alumilite also cuts like butter, holds threads readily and polishes up easily.

Apparently I did something wrong. I've got tons of circular scratches on the Alumilite and no amount of sanding seem to get rid of them. I'm using micromesh pads... I never have a problem with micromesh on Acrylic, or Rhino Plastics, or even Inlace Acrylester. But Alumilite...

Any suggestions?

Mike...

The description is:

Alumilite resin that is known for its beauty, resilience and durability. Alumilite also cuts like butter, holds threads readily and polishes up easily.

Apparently I did something wrong. I've got tons of circular scratches on the Alumilite and no amount of sanding seem to get rid of them. I'm using micromesh pads... I never have a problem with micromesh on Acrylic, or Rhino Plastics, or even Inlace Acrylester. But Alumilite...

Any suggestions?

Mike...