Texatdurango

Member

In another thread that I just replied to (http://www.penturners.org/forum/f13/tried-turning-between-centers-100576/) I touched on a topic that I don't believe I have ever seen discussed on the forum so what say we talk about it and compare some opinions!

How many times have we heard something akin to.... "I was almost finished turning the blank then WHAM... I got a CATCH and a chunk came flying off". Every time I read one of these posts I can't help but think... "How far was their tool rest from the blank when it happened?"

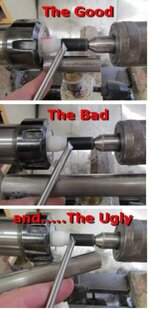

The closer your tool rest is to the blank, the less likely you are to get a catch...... regardless of what kind of cutting tool you are using! The farther the tool rest is from the blank, the greater the chance is of the tool trying to grab and take a nose dive over the tool rest!

Since the majority of us are self taught through trial and error with little formal training, how many of you pay attention to the distance between the tool rest and the blank or even know that it matters?

I taught myself how to (incorrectly) use a skew and at a local turning club meeting was complaining about what a crappy tool the skew was and how it caused catches one after another. So, the next weekend a seasoned turner invited me to his shop for some one-on one instruction and he taught me how to properly use a skew. When showing me how, he had the tool rest about 1/8" from the work piece. At that distance it is almost impossible to get a catch unless you really try. After a little practice, I learned the importance of tool control, which includes the all important tool rest position!

So, is anyone guilty of starting out with the tool rest in the proper position then not moving the rest closer in as they turn down the blank, thus widening the gap between rest and part?

http://www.penturners.org/forum/f13/tried-turning-between-centers-100576/

How many times have we heard something akin to.... "I was almost finished turning the blank then WHAM... I got a CATCH and a chunk came flying off". Every time I read one of these posts I can't help but think... "How far was their tool rest from the blank when it happened?"

The closer your tool rest is to the blank, the less likely you are to get a catch...... regardless of what kind of cutting tool you are using! The farther the tool rest is from the blank, the greater the chance is of the tool trying to grab and take a nose dive over the tool rest!

Since the majority of us are self taught through trial and error with little formal training, how many of you pay attention to the distance between the tool rest and the blank or even know that it matters?

I taught myself how to (incorrectly) use a skew and at a local turning club meeting was complaining about what a crappy tool the skew was and how it caused catches one after another. So, the next weekend a seasoned turner invited me to his shop for some one-on one instruction and he taught me how to properly use a skew. When showing me how, he had the tool rest about 1/8" from the work piece. At that distance it is almost impossible to get a catch unless you really try. After a little practice, I learned the importance of tool control, which includes the all important tool rest position!

So, is anyone guilty of starting out with the tool rest in the proper position then not moving the rest closer in as they turn down the blank, thus widening the gap between rest and part?

http://www.penturners.org/forum/f13/tried-turning-between-centers-100576/