PenWorks

Member

At the request of several memebers, I have been asked to do an article on casting polyester Resin ( PR ). I have not done so, as I thought it would be a redundancy of the excellant article I learned from, which was the Jay Pickens artile he wrote. Well I suggest to anyone to read it. as it is everything you need to know to cast PR and make your own great looking pen blanks.

I am just going to add to it and show more photos of the process and the supplies you need.

What I will not do is give you specific reciepes. Part of the fun of casting your own PR blanks, is coming up with your OWN individual colors and patterns. What fun would it be, if we all made the same looking blanks. Lately more folks around here have been starting to cast their own, I noticed some shades may be simular, but everybody seems to be making their own unique colors, which is GREAT. Once you have the basic concept down, the results are endless.... Yes, some will be duds, but hey, we all manage to break pens while turning.

Remember, the Cornel (god rest his soul) never gave his secret 11 herbs & spices

1. Materials. www.artstuf.com is where I buy ALL my casting materials except for the molds. They are a one stop shop for QUALITY dies. I buy my molds at www.misterart.com I ussually use a 2x3x1 (4 oz) & 6x3x1 (9 oz)

You will want to buy the powder dyes, I feel they give a deeper richer color with less transperancy, also you want the luster pigments, especially the white luster pigment, as you can mix this in with all your colors to get that pearl look.

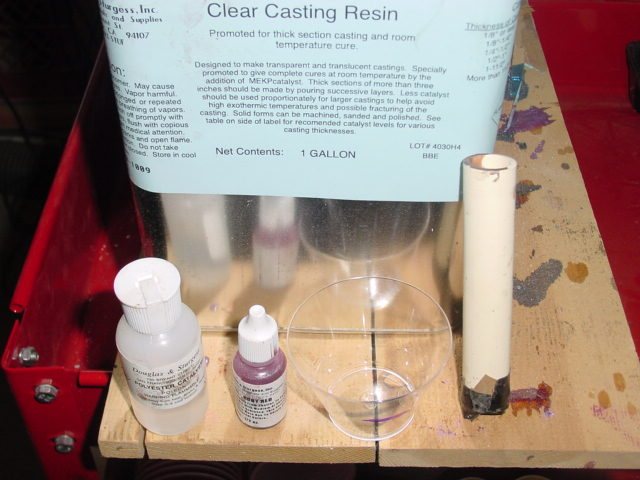

You need plastic cups, stir sticks, I buy the PR clear casting resin by the gallon and it comes with the hardener, about $33.00

So you can cast your PR blanks with as little as this

or as much as this

All my casting material is on a cart, as the odor (which I'm sure is not real good for your health) is a bit much. So I wheel my cart outside and do my casting there. Being in Arizona I am almost gauranteed a nice day

Here are some bronzing powders, they work good for other stuff, but not real good in mixing with PR. But maybe you can find the right combo, about $4.00 per bottle

Here are what the small bottles of powder & luster powder dyes look like. The big jug is the White pearl, that gets used allot.

Powder pigments are about $4.00-7.00 per bottle & luster $6.00-20.00

They will last you a long time!

The liquid PR resin dyes are 2.00 a bottle

2. First I pour water into whatever mold I am going to use,then I pour the water into a messuring cup to see how many OZ of PR I am mixing, then pour into my mixing cup and mark a line. This gives you the right amount of PR to pour into your cup. I allways pour in a touch more. Whatever leftover I have I pour into a piece of PVC and use that for center bands of something.

Next, stir in your hardener, I use 7 drops for every 1 OZ of PR.

After I mix it up for about two minutes I then add my powder dyes. This happens to be a 4 OZ mold 2x3x1 so I am adding 2 scoops of dye. One would work, but I want a real non transparent color. I stir this up for another couple minutes, then pour into the mold.

You can also add your white luster powder die at this time into the cup and stir if you want the white pearl look or any other color combo you want,then pour into the mold.

Now depending on the humidity and tempature, setting up can vary from 15-35 minutes, I stir mine occassionally to check the stiffness every 5 minutes waiting for that right time before it gels.

Now it has come to the gel stage, I am going to add some pearl drops and then gently stir, remember it has almost gelled, I am hoping to get some pearl highlights in this dark purple cast. This is the final stir and then that's it. It will fully harden in 4-8 hours. I ussually wait 24 hours before drilling and turning.

Here are some sample molds...I cut them on a band saw to the size blank I want. Also, the round casts are some of the left overs from my mixes. I pour them into PVC, you do not need a release agent as the PR will shrink when drying and just pop out of the mold.

Also, if you cast into a round clyinder mold, I have noticed it takes allot longer to set up and dry. Any time I pour into a PVC pipe mold, I don't even bother to look at it for at least a day or two.

Hear are some clear PR castings with snake skins

Well that's about it. All I can add is, it's fun and when you get good at it, it is allot cheaper than buying commercial produced resins. Also PR castings tend to turn easier as they are a touch softer.

A finished product, Purple Passion from Cave Creek Casting....

Now go get your gas masks....and have some FUN

I am just going to add to it and show more photos of the process and the supplies you need.

What I will not do is give you specific reciepes. Part of the fun of casting your own PR blanks, is coming up with your OWN individual colors and patterns. What fun would it be, if we all made the same looking blanks. Lately more folks around here have been starting to cast their own, I noticed some shades may be simular, but everybody seems to be making their own unique colors, which is GREAT. Once you have the basic concept down, the results are endless.... Yes, some will be duds, but hey, we all manage to break pens while turning.

Remember, the Cornel (god rest his soul) never gave his secret 11 herbs & spices

1. Materials. www.artstuf.com is where I buy ALL my casting materials except for the molds. They are a one stop shop for QUALITY dies. I buy my molds at www.misterart.com I ussually use a 2x3x1 (4 oz) & 6x3x1 (9 oz)

You will want to buy the powder dyes, I feel they give a deeper richer color with less transperancy, also you want the luster pigments, especially the white luster pigment, as you can mix this in with all your colors to get that pearl look.

You need plastic cups, stir sticks, I buy the PR clear casting resin by the gallon and it comes with the hardener, about $33.00

So you can cast your PR blanks with as little as this

or as much as this

All my casting material is on a cart, as the odor (which I'm sure is not real good for your health) is a bit much. So I wheel my cart outside and do my casting there. Being in Arizona I am almost gauranteed a nice day

Here are some bronzing powders, they work good for other stuff, but not real good in mixing with PR. But maybe you can find the right combo, about $4.00 per bottle

Here are what the small bottles of powder & luster powder dyes look like. The big jug is the White pearl, that gets used allot.

Powder pigments are about $4.00-7.00 per bottle & luster $6.00-20.00

They will last you a long time!

The liquid PR resin dyes are 2.00 a bottle

2. First I pour water into whatever mold I am going to use,then I pour the water into a messuring cup to see how many OZ of PR I am mixing, then pour into my mixing cup and mark a line. This gives you the right amount of PR to pour into your cup. I allways pour in a touch more. Whatever leftover I have I pour into a piece of PVC and use that for center bands of something.

Next, stir in your hardener, I use 7 drops for every 1 OZ of PR.

After I mix it up for about two minutes I then add my powder dyes. This happens to be a 4 OZ mold 2x3x1 so I am adding 2 scoops of dye. One would work, but I want a real non transparent color. I stir this up for another couple minutes, then pour into the mold.

You can also add your white luster powder die at this time into the cup and stir if you want the white pearl look or any other color combo you want,then pour into the mold.

Now depending on the humidity and tempature, setting up can vary from 15-35 minutes, I stir mine occassionally to check the stiffness every 5 minutes waiting for that right time before it gels.

Now it has come to the gel stage, I am going to add some pearl drops and then gently stir, remember it has almost gelled, I am hoping to get some pearl highlights in this dark purple cast. This is the final stir and then that's it. It will fully harden in 4-8 hours. I ussually wait 24 hours before drilling and turning.

Here are some sample molds...I cut them on a band saw to the size blank I want. Also, the round casts are some of the left overs from my mixes. I pour them into PVC, you do not need a release agent as the PR will shrink when drying and just pop out of the mold.

Also, if you cast into a round clyinder mold, I have noticed it takes allot longer to set up and dry. Any time I pour into a PVC pipe mold, I don't even bother to look at it for at least a day or two.

Hear are some clear PR castings with snake skins

Well that's about it. All I can add is, it's fun and when you get good at it, it is allot cheaper than buying commercial produced resins. Also PR castings tend to turn easier as they are a touch softer.

A finished product, Purple Passion from Cave Creek Casting....

Now go get your gas masks....and have some FUN