bitshird

Member

This is driving me even more nuts than I was to begin with ] The only book I have on wood turning is Turning Wood by Richard Raffan, the way it appears to me he is sharpening his skews with a crown or belly , I would have thought it would be better if it were hollow ground or a flat sided v,

] The only book I have on wood turning is Turning Wood by Richard Raffan, the way it appears to me he is sharpening his skews with a crown or belly , I would have thought it would be better if it were hollow ground or a flat sided v,

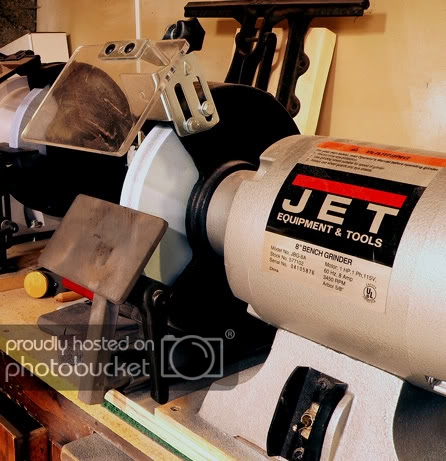

I really don't have any fancy machines to sharpen with yet, just a disc/belt sander and a crappy bench grinder, I have a Diamond wheeled lapidary grinder but I can't for the life of me get either of my skews near the wheels.

I've tried stoning the edges, they feel sharp, but my 1 in. just rides over the wood, I can get my 1/2 to cut for a short distance but then it digs in,

These were older Craftsman HSS and the steel seems pretty good, but I'm not sure the presentation angles were right to begin with, I can lay a 1 in gouge almost on edge and turn ribbons or at least long pieces, I managed to finally get one pen done today for my pen in the hat trade, but I would really like to learn to cut with a skew,

I looked through 8 or 9 pages in search, but couldn't find any definitive answers or angles, some suggestions please

I really don't have any fancy machines to sharpen with yet, just a disc/belt sander and a crappy bench grinder, I have a Diamond wheeled lapidary grinder but I can't for the life of me get either of my skews near the wheels.

I've tried stoning the edges, they feel sharp, but my 1 in. just rides over the wood, I can get my 1/2 to cut for a short distance but then it digs in,

These were older Craftsman HSS and the steel seems pretty good, but I'm not sure the presentation angles were right to begin with, I can lay a 1 in gouge almost on edge and turn ribbons or at least long pieces, I managed to finally get one pen done today for my pen in the hat trade, but I would really like to learn to cut with a skew,

I looked through 8 or 9 pages in search, but couldn't find any definitive answers or angles, some suggestions please