You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help...Assembly advice...Please

- Thread starter Oimmuk

- Start date

Signed-In Members Don't See This Ad

- Status

- Not open for further replies.

Signed-In Members Don't See This Ad

mrcook4570

Member

Chamfer the tubes after milling or before assembly. Make sure ALL glue residue is removed from tubes. Use fingers to keep transmission lined up with tube while pressing it in. Rotate blank 90 degrees several times during assembly.

For length - don't rely on the line on the transmission. Either make a stop block for desired length or check length by inserting refill periodically during assembly.

For length - don't rely on the line on the transmission. Either make a stop block for desired length or check length by inserting refill periodically during assembly.

Randy_

Member

What sort of tool are you using to assemble your pens?

As to the cracking question, do you mean during assembly or at some other time during the process??

As to the cracking question, do you mean during assembly or at some other time during the process??

bob393

Member

Straight advice.

That's all I do using a drill press as a press.

That's all I do using a drill press as a press.

Originally posted by mrcook4570

<br />Chamfer the tubes after milling or before assembly. Make sure ALL glue residue is removed from tubes. Use fingers to keep transmission lined up with tube while pressing it in. Rotate blank 90 degrees several times during assembly.

For length - don't rely on the line on the transmission. Either make a stop block for desired length or check length by inserting refill periodically during assembly.

Rifleman1776

Member

Keep it straight. A pen press is a huge help with this step. It can be done other ways, but the press is the best choice.

I dont have a pen press yet, I have used a large C-clamp with wooden blocks and also a raw hide mallet.

As for when it cracks, it varies the most frustraiting is on the lathe or after I finish it out before assembly, and also at assembly.

I had not even thought of rotating the pen during assembly like Mrcook said...Thanks there.

How shoule I go about setting up a stop block? Insert the refill into the transmission and extend into open position thne measure the legnth minus what I want tip extension tp be? Would this be the correct proceedure?

As for when it cracks, it varies the most frustraiting is on the lathe or after I finish it out before assembly, and also at assembly.

I had not even thought of rotating the pen during assembly like Mrcook said...Thanks there.

How shoule I go about setting up a stop block? Insert the refill into the transmission and extend into open position thne measure the legnth minus what I want tip extension tp be? Would this be the correct proceedure?

mrcook4570

Member

Originally posted by Oimmuk

<br />

As for when it cracks, it varies the most frustraiting is on the lathe or after I finish it out before assembly, and also at assembly.

Sounds like your wood may still be wet.

Russb

Member

I use a stop block on my slimlines and some other kits once I know the proper depth I make the appropriate block. If I have time I will drill my blanks, to proper size, and let them sit in the shop until I am ready to turn them, sometimes for weeks. Does this assist in drying? It can't hurt. Before gluing I make sure the brass fits and redrill if needed. Get rid of the mallet. Using the clamp is ok if that is what you have but use slow steady pressure. Other suggestions are also excellent. Make sure the inside of the tubes are clean. I use a hand held countersink to chamfer the tubes. Makes all parts assemble easier.

sandking

Member

Go to Woodcraft an pick up a 12" Bessey. They are on sale for $19 and use that to insert your fittings. I have never had a problem with myh Bessey K body clamp to assemble pens or bottle stoppers.

kirkfranks

Member

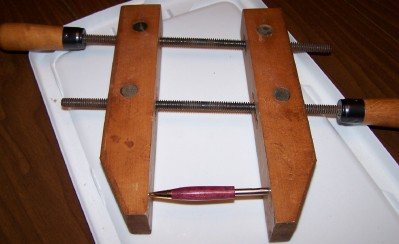

If you have one you may also want to try using a Handscrew Clamp instead of the C Clamp. Since there is no Swivel pad things go much straighter.

<br />

<br />

I started this way before I made a pen press. I still use the clamp if I only have one or two pens to make because I think it gives me better control. Since you are using the twist on the handle to press the parts you never get the part start to move and then all of a sudden go too far. You can also use one hand to twist while the other hand gets parts going straight.

I started this way before I made a pen press. I still use the clamp if I only have one or two pens to make because I think it gives me better control. Since you are using the twist on the handle to press the parts you never get the part start to move and then all of a sudden go too far. You can also use one hand to twist while the other hand gets parts going straight.

Rifleman1776

Member

Get rid of the mallet.

Originally posted by Oimmuk

<br />I dont have a pen press yet, I have used a large C-clamp with wooden blocks and also a raw hide mallet.

As for when it cracks, it varies the most frustraiting is on the lathe or after I finish it out before assembly, and also at assembly.

I had not even thought of rotating the pen during assembly like Mrcook said...Thanks there.

How shoule I go about setting up a stop block? Insert the refill into the transmission and extend into open position thne measure the legnth minus what I want tip extension tp be? Would this be the correct proceedure?

This is a recipe for disaster unless the user knows enough to turn both handles.Originally posted by kirkfranks

<br />If you have one you may also want to try using a Handscrew Clamp instead of the C Clamp. Since there is no Swivel pad things go much straighter.

<br />

I started this way before I made a pen press. I still use the clamp if I only have one or two pens to make because I think it gives me better control. Since you are using the twist on the handle to press the parts you never get the part start to move and then all of a sudden go too far. You can also use one hand to twist while the other hand gets parts going straight.

If necessary use your drill press or even your lathe

Awoodfan

Member

My favorite assembly tool is a 4" vise which gives me the ultimate in control. Just picture it as a horizontal arbor press.

Ron

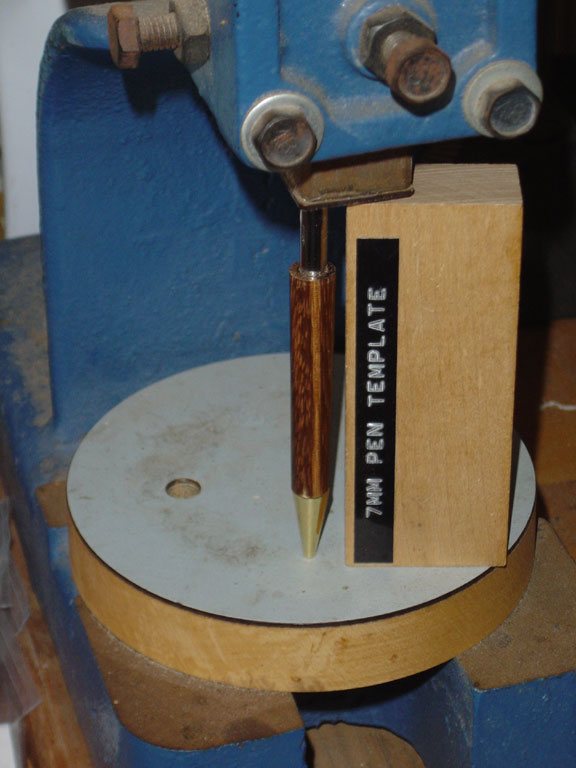

<b>Image Insert:</b><br />

<br />

<br />

Ron

<b>Image Insert:</b><br />

tnilmerl

Member

As far as a stop block, you have to have a (correctly) finished pen first. I take an 18" piece of 1x2 pine, route a channel with a v-bit down the length. I then take the barrel I want a depth guide for and measure it for length (lay it into the groove and mark length). I then cut off the measured piece (a little bit long). I sand the block down on the disk sander to get the final correct length. Ends need to be square to the v-channel. Now, when I want to squeeze in the transmission (I use either a machinist vise or a workbench vise), I lay the tube (with the nib already pressed in) and the transmission into the v-channel and squeeze parts together.

When I teach a pen turning class, I show the students how to make this depth gauge. Using the long piece of wood (18") has the added benefit in that the remaining piece is given to my students to use as a layout tray to place all the parts, in proper sequence, prior to assembly. (I can hear the oooh, aaaahhh! now....)

When I teach a pen turning class, I show the students how to make this depth gauge. Using the long piece of wood (18") has the added benefit in that the remaining piece is given to my students to use as a layout tray to place all the parts, in proper sequence, prior to assembly. (I can hear the oooh, aaaahhh! now....)

- Status

- Not open for further replies.