You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HELP!

- Thread starter ladycop322

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

bkersten

Member

Does the cap come off to change the refill, or how is that done? I had slims where I could take the refill out and fit a steel punch from PSI down through the trans and punch out the nib and then fix whatever, and then press back in the nib. I've not had this kit yet so I'm not rreal familiar with what the top looks like in detail. There should be a way to salvage it. Bob

tbroye

Member

From the picture it look slike the blank is not square to the tip and doesn't fit flush. I have had that problem with some I have made. I have manage to disassemble them and true up the end carefully and reassemble. Do you have a set of the Harbour Freight transfer punches they make it easy to take pens apart. Good luck By the way it is a pretty pen. Like the blank and the kit.

ladycop322

Member

OK GUYS

I can remove the tip of the pen from the blank but at the cap end, there is a mechanism that assists in twisting the pen itself to allow the ink tip to protrude when in use. I cannot punch the cap because it will destroy that mechanism. The cap does not pull off either.

I can remove the tip of the pen from the blank but at the cap end, there is a mechanism that assists in twisting the pen itself to allow the ink tip to protrude when in use. I cannot punch the cap because it will destroy that mechanism. The cap does not pull off either.

seamus7227

Member

S.O.L. if you cant remove the tip.

Dalecamino

Local Chapter Leader

File it in the failure drawer and, make another one. Easy fix :biggrin:

stonepecker

Member

This is one of those times that you might have to call this a learning experience.

Keep it for yourself or put it by your phone. I have a cup with pens in, by the phone , cause it never fails that I need one for certain calls.

Keep it for yourself or put it by your phone. I have a cup with pens in, by the phone , cause it never fails that I need one for certain calls.

Either the blank or kit is not square in relation to the center axis of the blank or perpendicular...your choice. As a "Professional" pen turner, these things should have been addressed prior to assembly. Buy another and try again.

jjjaworski

Member

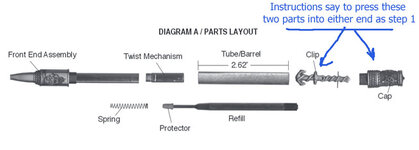

That is a bit of a bugger to take apart. I just looked at the PSI website and the assembly instructions for this pen kit.

My only thought is if you could drill a hole in a thin piece of metal and try to make an inertia puller by sandwiching it in between the front assembly with the nib and the pen barrel.

By using a method similar to a hammer inertia bullet puller you might be able to get the twist mechanism to budge.

It would be better if you could find a bolt with the same thread as the twist mechanism and used that instead. Just a thought.

My only thought is if you could drill a hole in a thin piece of metal and try to make an inertia puller by sandwiching it in between the front assembly with the nib and the pen barrel.

By using a method similar to a hammer inertia bullet puller you might be able to get the twist mechanism to budge.

It would be better if you could find a bolt with the same thread as the twist mechanism and used that instead. Just a thought.

chuckw3

Member

I can remove the tip of the pen from the blank but at the cap end, there is a mechanism that assists in twisting the pen itself to allow the ink tip to protrude when in use. I cannot punch the cap because it will destroy that mechanism. The cap does not pull off either.

If you can remove the tip mark the edge that needs trimming,remove the tip and hand file or sand until you get a fit. Be gentle take it slow it can be done.

Chuck

Lance

Member

How about going to a gun/reloading store and getting a bullet puller. ( looks like a plastic hammer ) the nib would go into one of the faces of the hammer. If that makes sense ? I've pulled many a bullet that way .

wyone

Member

so if all else fails... I wonder about taking a needle or something and lightly applying some CA to fill the gap. My thoughts are, you need to take away the visual aspect of the gap, but thinking, maybe the darkness might still show through the CA. Hmmm and is really is a great turning too

Michelle,

I think you should be able to square up the tip end without having to take off the cap end.

How do you square up your blanks on 3/8" tubes like this? Personally, I make my own squaring sleeves by simply making a standard 7 mm slimline barrel with some cheap wood and turning it down to just fit into a 3/8" tube, then I use a standard 7 mm barrel trimmer.

If you do something like that, you can just remove the tip, leave the cap in place and slide the trimming sleeve into the tube and carefully square up the end of the blank. If a standard length 7mm tube makes too long of trimming sleeve with the cap in place, you can just cut the trimming sleeve down a bit so it will fit all the way into the 3/8" tube without bumping against the cap end.

Rather than a standard barrel trimmer, I would opt for a trimmer with a sanding disk like the ones Rick Herrell makes if you have one or if you have time to wait for one. If you have to use a standard barrel trimmer, I would work it by hand rather than with a drill.

Send me a PM if you have any questions about this and I'll be glad to help you work through it.

Best regards

Edgar

I think you should be able to square up the tip end without having to take off the cap end.

How do you square up your blanks on 3/8" tubes like this? Personally, I make my own squaring sleeves by simply making a standard 7 mm slimline barrel with some cheap wood and turning it down to just fit into a 3/8" tube, then I use a standard 7 mm barrel trimmer.

If you do something like that, you can just remove the tip, leave the cap in place and slide the trimming sleeve into the tube and carefully square up the end of the blank. If a standard length 7mm tube makes too long of trimming sleeve with the cap in place, you can just cut the trimming sleeve down a bit so it will fit all the way into the 3/8" tube without bumping against the cap end.

Rather than a standard barrel trimmer, I would opt for a trimmer with a sanding disk like the ones Rick Herrell makes if you have one or if you have time to wait for one. If you have to use a standard barrel trimmer, I would work it by hand rather than with a drill.

Send me a PM if you have any questions about this and I'll be glad to help you work through it.

Best regards

Edgar

Last edited:

How is the transmission installed? is it press fit or screw in.

Mr Vic

Member

Michelle, when you take it apart to replace the refill, are you unscrewing the nib or pulling it out? Don't unscrew it but rather pull and the transmission/twist mechanism will come out with the nib. It's a a snug press fit into the barrel. it's a designed Similar to the Wall St II/Sierra. To confirm this can you twis the barrel after the point is fully extended?

At that point you can use a punch to remove the cap/clip if desired or just square up tha end while assembled.

Herre's a link to Instructions.... http://www.pennstateind.com/library/PKNAUTXX_INS.pdf

At that point you can use a punch to remove the cap/clip if desired or just square up tha end while assembled.

Herre's a link to Instructions.... http://www.pennstateind.com/library/PKNAUTXX_INS.pdf

Last edited:

ladycop322

Member

This reply is ONLY for Jim Burr:

Mr. Burr -

I am going to be nice since it is the holidays...I believe I had an issue with you in the past about your being SO rude to members of this forum. If it were up to me, I would so kick you out! You are the 'UN'professional one here, sir. Didn't your mother EVER teach you that if you have nothing nice to say, then don't say it?

I never claimed to be a professional pen turner. I am learning every single day with every pen I make. I do not claim to be perfect. I can admit, because I am a human being with feelings and emotions, unlike yourself, that it has been an off day for me. I have a dad with not one type of cancer, but TWO who has always been a go-getter and NEVER complained or was RUDE, unlike yourself. My daughter is a chemo patient at 29....and my son happens to be sick, in bed, for the past 1.5 weeks. I also hold down a stressful job protecting people and property, even if they happen to be RUDE! I have to deal with people like you every single day on my beat and I thought I could come here to find a little human kindness. I appreciate all members who have helped me past and present - thank you. Please, MR. BURR, do me a favor and do not respond to my postings if you can help it.

Happy holidays and I hope Santa has some kindness in his heart and doesn't put COAL in your stocking this Christmas! Maybe next year, if you are a good, kind boy, you will get a nice present under the tree.

Have a Merry Christmas and a Happy New Year, sir. I would gladly give you mine if you would like it.

Michelle

Mr. Burr -

I am going to be nice since it is the holidays...I believe I had an issue with you in the past about your being SO rude to members of this forum. If it were up to me, I would so kick you out! You are the 'UN'professional one here, sir. Didn't your mother EVER teach you that if you have nothing nice to say, then don't say it?

I never claimed to be a professional pen turner. I am learning every single day with every pen I make. I do not claim to be perfect. I can admit, because I am a human being with feelings and emotions, unlike yourself, that it has been an off day for me. I have a dad with not one type of cancer, but TWO who has always been a go-getter and NEVER complained or was RUDE, unlike yourself. My daughter is a chemo patient at 29....and my son happens to be sick, in bed, for the past 1.5 weeks. I also hold down a stressful job protecting people and property, even if they happen to be RUDE! I have to deal with people like you every single day on my beat and I thought I could come here to find a little human kindness. I appreciate all members who have helped me past and present - thank you. Please, MR. BURR, do me a favor and do not respond to my postings if you can help it.

Happy holidays and I hope Santa has some kindness in his heart and doesn't put COAL in your stocking this Christmas! Maybe next year, if you are a good, kind boy, you will get a nice present under the tree.

Have a Merry Christmas and a Happy New Year, sir. I would gladly give you mine if you would like it.

Michelle

wyone

Member

Very classy Michelle.. seriously  I would take it as a compliment that you are being classified as a professional turner. I have seen the quality of your work, and in my humble opinion, it is that good. I am making progress every time I turn, and think that will never change. I expect to improve with every turning. You, on the other hand, have little, if any room for improvement. I have to say, when I see that quality turners such as you have issues, it helps me to accept that things sometimes just happen.

I would take it as a compliment that you are being classified as a professional turner. I have seen the quality of your work, and in my humble opinion, it is that good. I am making progress every time I turn, and think that will never change. I expect to improve with every turning. You, on the other hand, have little, if any room for improvement. I have to say, when I see that quality turners such as you have issues, it helps me to accept that things sometimes just happen.

On a side note, thank you risking your life every day for those who may or may not appreciate you. Rest assured, there are a LOT of us who respect and are very grateful for you.

On a side note, thank you risking your life every day for those who may or may not appreciate you. Rest assured, there are a LOT of us who respect and are very grateful for you.

jsmithmarcus

Member

Well said Michelle! I always look forward to Jim Burr coments :rolleyes Merry Christmas Michelle!

ladycop322

Member

Thanks guys!

Thank you guys! I, being an ARIES, and a LEO, cannot and will not allow someone to disrespect me, EVER! I always speak up! (Oh, wait, it could be the Italian in me too! Thanks to my daddy!

Thank you guys! I, being an ARIES, and a LEO, cannot and will not allow someone to disrespect me, EVER! I always speak up! (Oh, wait, it could be the Italian in me too! Thanks to my daddy!

I think Mr Vic is right, it looks to me like the cap presses into the tube to hold the clip. The transmission / twist mechanism should pull out of the cap with the nib end of the pen.

Looks like you need to lightly trim the nib end of the tube, once the guts are out of the way. You can slide the cutter on a 7mm trimmer up on the shaft, so there is an inch or so of shaft extending past the cutter, and make a bushing to fit the 7mm shaft and the inside diameter of the tube.

Good luck!

Looks like you need to lightly trim the nib end of the tube, once the guts are out of the way. You can slide the cutter on a 7mm trimmer up on the shaft, so there is an inch or so of shaft extending past the cutter, and make a bushing to fit the 7mm shaft and the inside diameter of the tube.

Good luck!

I think Mr Vic has it. It might be a hard pull to get the tip assembly and transmission out of the tube but I think you can do it. I don't think the cap is actually involved in operating the pen.

Dale Allen

Member

Michelle, let me give this a shot.

I studied the instructions and, correct me if this is wrong, the twist function is between the main barrel and the pen tip assembly. In other words, the area you are seeing the gap is where the 2 sections rotate. Is that correct?

That is the way the instructions read and it looks like you would unscrew the main pen body from the tip assembly when you need to change the refill.

As pictured below, I see no way for the cap assembly to be the only part that turns the twist mechanism. If that is the case then the main pen body should unscrew from the tip by unscrewing the threaded twist mechanism. And, if that is the case, you may then be able to drive the tip assembly off and redo the blank.

Can you take some detailed pictures of the pieces that you can take apart?

This is a new kit and there is no history to search so you are on new territory here.

I studied the instructions and, correct me if this is wrong, the twist function is between the main barrel and the pen tip assembly. In other words, the area you are seeing the gap is where the 2 sections rotate. Is that correct?

That is the way the instructions read and it looks like you would unscrew the main pen body from the tip assembly when you need to change the refill.

As pictured below, I see no way for the cap assembly to be the only part that turns the twist mechanism. If that is the case then the main pen body should unscrew from the tip by unscrewing the threaded twist mechanism. And, if that is the case, you may then be able to drive the tip assembly off and redo the blank.

Can you take some detailed pictures of the pieces that you can take apart?

This is a new kit and there is no history to search so you are on new territory here.

Attachments

ladycop322

Member

Dale,

I can easily take the nib assembly off no problem. Inside where the cap and clip are is a other mechanism that inserted in that position when I first assembled the pen. If I punch the cap assembly off from the inside the I will damage it and the pen won't function I will send pics shortly.

Thank you

I can easily take the nib assembly off no problem. Inside where the cap and clip are is a other mechanism that inserted in that position when I first assembled the pen. If I punch the cap assembly off from the inside the I will damage it and the pen won't function I will send pics shortly.

Thank you

ladycop322

Member

This is the problem....

The twist mechanism is inside the cap! Here is a picuture. First is all three pieces that I have taken apart. My mission today is to get the cap off without damaging the twist mechanism inside the cap. Maybe it doesn't belong there but that is where it decided to take up space lol.

The twist mechanism is inside the cap! Here is a picuture. First is all three pieces that I have taken apart. My mission today is to get the cap off without damaging the twist mechanism inside the cap. Maybe it doesn't belong there but that is where it decided to take up space lol.

Attachments

When you assembled the pen, after pressing on the cap and clip, did you screw the transmission onto the front end assembly before installing? It looks like from the instructions, like the others were saying, that the whole front assembly with the transmission should pull out unless the transmission came unscrewed.

bgio13

Member

I did something similar to what Edgar was describing. I have a trimmer that has the same diameter shaft so I just loosened the set screw and moved the trimmer to the end of the shaft, chuck it in a hand drill and go slow. Oh, and use some sort of glove to protect your hand, and the pen, good luck, hope this helps,

Bill

Bill

Attachments

ladycop322

Member

Transmission came unscrewed. Assembled the way the manual explained.

Michelle

Michelle

Yes, thats what it looks like. The transmission came unscrewed in the tube. I don't know if you can find a long bolt with the same threads that you could screw into the transmission to pull it out. Next time you might want to us lock tight on those threads.

I think you can fix your pen without removing the cap. You should be able to make a trimmer that will square the end of the blank without going all the way to the cap end of the pen. Use a 7mm trimmer like shown above, and make a bushing to fit the trimmer shaft to the pen barrel.

Can you screw the nib end back on to the transmission? Or has the transmission slipped too far into the cap?

Can you screw the nib end back on to the transmission? Or has the transmission slipped too far into the cap?

Last edited:

ladycop322

Member

I did it! I got it apart without damage! Next question is this....

If I barrel trim to 'round' the edge that was off, won't that make it too short for the components and show a gap anyway? If so, I can just remake the tube but would rather spend that time doing more productive things

If I barrel trim to 'round' the edge that was off, won't that make it too short for the components and show a gap anyway? If so, I can just remake the tube but would rather spend that time doing more productive things

I don't think it will...but if it does a thin washer at the tip end would fix it and could look like it was part of the pen.

raar25

Member

Michelle try putting a generous chamfer on the inside of your tube and see how it fits before you trim the end. If the tube ID edge is too sharp it wont go all the way on if the metal parts have a radius. I had a wall st II from wood craft which had this problem. Also you may want to use the barrel trimmer head backwards with sand paper glued to the flat side which is alot more gentle than the cutting teeth.

Good luck,

Ray

Good luck,

Ray

nativewooder

Member

Congrats on your dis-assembly! Perhaps if you get the parts square to each other and then still have a gap, you could make a custom trim ring to fill the gap. Or not. I know you're probably aggravated and frustrated, so set it aside and take a day or two forget about it.:wink:

Ray's suggestion about using the barrel trimmer in reverse with some stick-on or glued-on sandpaper is a great alternative if you don't have an actual sanding mill.

Personally, I would not use a barrel trimmer in a drill on a fully turned blank. The ends of the blank are very thin and the slightest catch could easily ruin the blank. Sanding mills (or sandpaper on a reversed trimming mill) are the ideal tool for final fit touch-up, before or after turning.

You can put the sanding mills into a drill, but I almost always just use them by hand so I can just sand off minute amounts at a time and closely watch the process.

Personally, I would not use a barrel trimmer in a drill on a fully turned blank. The ends of the blank are very thin and the slightest catch could easily ruin the blank. Sanding mills (or sandpaper on a reversed trimming mill) are the ideal tool for final fit touch-up, before or after turning.

You can put the sanding mills into a drill, but I almost always just use them by hand so I can just sand off minute amounts at a time and closely watch the process.

ladycop322

Member

Thank you everyone for all your input! It helped immensely. Now, to request PRAYER for my daughter...she was at her chemo appt today and had a terrible reaction. When she got home it worsened and she had to be transported to ER with the medics assisting her in breathing  So young to have to go through all this! I KNOW there is power in prayer...so please if you can take a moment to bow your head and just ask that she be healed or at least get some comfort. Thank you all again

So young to have to go through all this! I KNOW there is power in prayer...so please if you can take a moment to bow your head and just ask that she be healed or at least get some comfort. Thank you all again

Love

Michelle

Love

Michelle

So sorry to hear about your daughter's added burdens.

Janis & I will certainly keep her in our prayers along with all the rest of your family.

Janis & I will certainly keep her in our prayers along with all the rest of your family.

wyone

Member

Prayers sent....

Signed-In Members Don't See This Ad

Jim15

Member

Michelle, I will be praying for your daughter.