Rmartin

Member

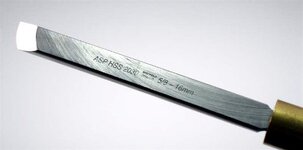

I use a round nosed skew from start to finish. I sometimes use a straight edged skew for detail and bead work. But my question doesn't have anything to do with the point of the tool, rather the shape of the tool which rests on the tool bar.

My favorite tool is one that has a flat profile. The thing is, it seems my more expensive tools have a round profile. Is this just a preference issue, or a something else? Is the flat tool a training wheels tool? If I want to grow up to be a real turner, do I need to learn how to use a tool with a round profile where it rests on the tool bar?

Which type of tool do you prefer?

My favorite tool is one that has a flat profile. The thing is, it seems my more expensive tools have a round profile. Is this just a preference issue, or a something else? Is the flat tool a training wheels tool? If I want to grow up to be a real turner, do I need to learn how to use a tool with a round profile where it rests on the tool bar?

Which type of tool do you prefer?