rbaron

Member

Hi all,

I bought an Excelsior Mini Lathe from Rockler. I have a few questions.

1. The lathe came with a face plate installed. Do I need to keep it there to turn pens?

2. When I put my blanks on the mandrel and the bushings and start to turn, the blanks sometimes stop spinning. How do I get the blanks on the mandrel so they wont stop spinning?

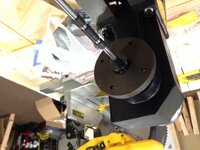

I don't know why this photo is upside down???

I bought an Excelsior Mini Lathe from Rockler. I have a few questions.

1. The lathe came with a face plate installed. Do I need to keep it there to turn pens?

2. When I put my blanks on the mandrel and the bushings and start to turn, the blanks sometimes stop spinning. How do I get the blanks on the mandrel so they wont stop spinning?

I don't know why this photo is upside down???