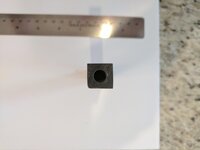

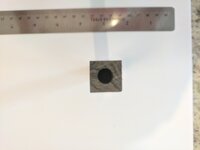

Since I started penturning (only a few months ago) I've drilled using my lathe. I've made some improvements to my process along the way and have had decent results, but this one ended up so good I decided I had to post it. I've struggled with the bit heating up and also drifting. Since this is a modified slim and I am using a 1/2 inch blank, I decided to take it really slow and cool the bit with a damp paper towel each time I cleared the chips. I haven't come across anyone recommending this - wondering if anyone else does it, and if there are any pitfalls I'm not seeing. I don't really see any downsides, other than time and maybe problems with excess water.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling Success

- Thread starter Dehn0045

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

NLAlston

Member

Since I started penturning (only a few months ago) I've drilled using my lathe. I've made some improvements to my process along the way and have had decent results, but this one ended up so good I decided I had to post it. I've struggled with the bit heating up and also drifting. Since this is a modified slim and I am using a 1/2 inch blank, I decided to take it really slow and cool the bit with a damp paper towel each time I cleared the chips. I haven't come across anyone recommending this - wondering if anyone else does it, and if there are any pitfalls I'm not seeing. I don't really see any downsides, other than time and maybe problems with excess water.

Hi Sam.

Just last night, in fact, I happened across a YouTube video where the presenter did the very same thing. His name is Lacy (LL Woodworks), and he always has videos with very helpful content, that he's sharing.

Now, I don't know if he's does that cooling procedure on all of his pen blanks but, last night, this particular video showed him working with a blank that he had segmented. He had epoxied a sliver of aluminum between two sections of a cut pen blank, and mentioned as to how built up heat - of the bit - could weaken the epoxy, and cause the merged parts to fail.

Any downsides mentioned? Well, he did say that he was using alcohol to cool the bit. He would use water when working with acrylics, but preferred alcohol - when working with wood - because of the fact that water is a grain raising element.

So, I really don't think that you have anything, other than that last factor, to be concerned about. It is surely something that I'm going to be adding to my workflow.

mecompco

Member

I keep a spray bottle of DNA handy to cool my bit/blank. However, it is flammable, and I do not recommend its use (though I've never had a problem).

Regards,

Michael

Regards,

Michael

robutacion

Member

The "cooling" process of the drill bit, has been recommended time and time again, I could mention a few different processes but they all offer the same results in the end.

I'm glad that you manage to find a way to do it that works well for you, the results were pretty damn good, for sure...!

Cheers

George

I'm glad that you manage to find a way to do it that works well for you, the results were pretty damn good, for sure...!

Cheers

George